Contract No.

HY/2010/02 – Hong Kong-Zhuhai-Macao Bridge Hong Kong Boundary Crossing

Facilities – Reclamation Work (here below, known as “the Project”) mainly

comprises reclamation at the northeast

of the Hong

Kong International Airport

of an area

of about 130-hectare

for the construction of an

artificial island for the development of the Hong Kong Boundary Crossing

Facilities (HKBCF), and about 19-hectare for the southern landfall of the Tuen

Mun - Chek Lap Kok Link (TMCLKL). It is a designated project and is governed by

the current permits for the Project, i.e. the amended Environmental Permits

(EPs) issued on 06 August 2013 (EP-353/2009/G) and 28 January

2014 (EP-354/2009/B) (for TMCLKL Southern Landfall Reclamation only).

Ove Arup

& Partners Hong Kong Limited (Arup) was appointed by Highways Department

(HyD) as the consultants for the design and construction assignment for the

Project’s reclamation works (i.e. the Engineer for the Project).

China

Harbour Engineering Company Limited (CHEC) was awarded by HyD as the Contractor

to undertake the construction work of the Project.

ENVIRON Hong

Kong Ltd. was employed by HyD as the Independent Environmental Checker (IEC)

and Environmental Project Office (ENPO) for the Project.

AECOM Asia

Co. Ltd. (AECOM) was appointed by CHEC to undertake the role of Environmental

Team for the Project for carrying out the environmental monitoring and audit

(EM&A) works.

The

construction phase of the Project under the EPs was commenced on 12 March 2012

and will be tentatively completed by early Year 2016. The EM&A programme,

including air quality, noise, water quality and dolphin monitoring and

environmental site inspections, was commenced on 12 March 2012.

This report documents the findings

of EM&A works conducted in the period between 1 and 30 September 2014. As informed by the Contractor, major activities in

the reporting period were:-

Marine-based Works

-

Cellular structure installation

-

Optimizing rubble mound seawalls

-

Conforming sloping seawalls

-

Laying geo-textile

-

Sand blanket laying

-

Sand filling

-

Rock filling

-

Maintenance of silt curtain & silt screen at sea water intake of

HKIA

-

Band drain installation

-

Backfill cellular structure

-

Geotechnical Instrumentation works

-

Surcharge laying

-

Capping Beams structures

-

Construction of temporary jetties for surcharge laying

-

Temporary Watermain construction

-

Flat barge of unloading public fill for surcharge laying

-

Precast Yard Setup

Land-based Works

-

Maintenance works of Site Office at Works Area WA2

-

Maintenance works of Public Works Regional Laboratory at Works Area

WA3

-

Maintenance of Temporary Marine Access at Works Area WA2

A summary of monitoring and audit activities

conducted in the reporting period is listed below:

|

24-hour Total Suspended Particulates (TSP)

monitoring

1-hour TSP monitoring

|

6 sessions

6 sessions

|

|

Noise monitoring

|

5 sessions

|

|

Impact water quality monitoring

|

13 sessions

|

|

Impact dolphin monitoring

|

2 surveys

|

|

Joint Environmental site inspection

|

4 sessions

|

Breaches

of Action and Limit Levels for Air Quality

All 1-Hour TSP and 24-hour TSP results were

below the Action and Limit Level in the reporting month.

Breaches of Action and

Limit Levels for Noise

For construction noise, no

exceedance was recorded at all monitoring stations in the reporting period.

Breaches

of Action and Limit Levels for Water Quality

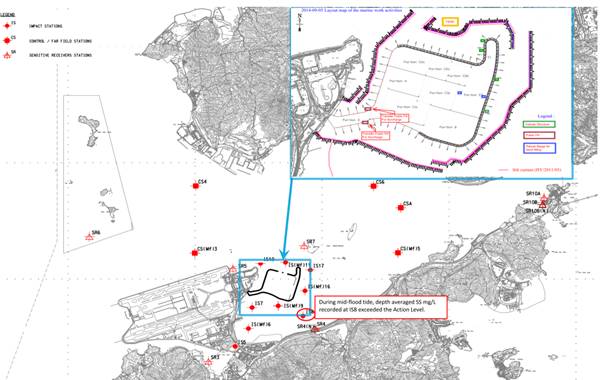

Total of (4) four Action

Level Exceedances of SS were recorded in this reporting month. (1) One Action Level

Exceedance of SS at IS8 at mid-flood tide on 5 September 2014, (2) Two Action

Level Exceedances of SS at IS5 and SR3 respectively at Mid-Ebb tide were

recorded on 10 September 2014 and (1) one Action level exceedance of SS were

recorded at SR10B(N) at Mid-Flood tide on 12 September 2014. After

investigation, the exceedances was considered to be non-project related.

Impact Dolphin Monitoring

A total of six sightings

were made, three “on effort” and three “opportunistic”. Two sightings were made on the 22 September

2014 in NWL and four sightings were made on 29 September 2014 also in NWL. A total of twenty-two individuals were

sighted from the two impact dolphin surveys in the reporting period. Sighting

details are summarised and plotted in Appendix K and Figure 5c, respectively.

Behaviour: Of the six

sightings , three groups were feeding, one in association with a purse seine

trawler, two groups were travelling, one group was engaged in multiple

activities, which comprised feeding and surface active behaviours. The

locations of sighting with different behaviour are mapped in Figure 5d.

Two calves were recorded in

September 2014, however, only one calf came close enough to photograph and it’s

mother has not been identified. The location of sighting with calf is mapped in

Figure 5e.

Complaint, Notification of Summons and

Successful Prosecution

Three environmental complaints have been received in

September 2014.

As informed by the Contractor on 15 Sept 14,

there is an environmental complaint received on 29 August 14 by HyD. The

complainant who lives at Tower 4, Melody Garden, Tuen Mun called reflecting

environmental issues arisen from many sand barges in the waters facing her

apartment. According to the complainant, sand was blown into her apartment

because the barges were not covered and it was worse when sand was transferred

from one vessel to another on conveyor belts. After investigation, there is no

adequate information to conclude the observed impact is related to this

Contract.

As informed by the Contractor, a public

complaint has been received by ICC on 9 September 2014 and it was referred to

this Contract, the complainant raised concern about a large amount of general

refuse such as food container and plastic bottles were observed on sea area off

the Gold Coast, Tuen Mun. After investigation, there is no adequate information

to conclude the observed impact is related to this Contract.

An air quality complaint has been received by

the Contractor on 29 September 2014 via email. The complaint was first received

by EPD via email on 5 September 2014 and it was referred by EPD to the HZMB HK

Project Management Office (Management Office) to handle the complaint directly

on 10 September 2014 following the request of the complainant. The Management

Office responded to the complainant directly on 17 September 2014. Subsequently, the complainant followed up

with the response given by the Management Office and complained again on 26

September 2014. This follow up complaint was

referred to the project team to investigate. The complainant complained

that many of the sand barges did not stay at area of reclamation works near

Chek Lap Kok or at the sea area near Tuen Mun River Trade Terminal but moored

in the sea area close to Melody Garden. Sand were easily blown to the inside

house during days with moderate wind.

The complainant suggested that, sand barges should be requested to move

away from residential areas and sand barges should be provided with cover

fabric and sprinkling to minimise environmental pollution caused by sand. After

investigation, there is no adequate information to conclude the observed impact

is related to this Contract.

No

notification of summons or prosecution was received in the reporting period.

Reporting Change

There was no reporting change

required in the reporting period.

Future Key Issues

Key issues to be considered in

the coming month included:-

-

Site runoff should be properly collected and treated prior to discharge;

-

Minimize loss of sediment from filling works;

-

Regular review and maintenance of silt curtain systems, drainage systems

and desilting facilities;

-

Exposed surfaces/soil stockpiles should be properly treated to avoid

generation of silty surface run-off during rainstorm;

-

Regular review and maintenance of wheel washing facilities provided at

all site entrances/exits;

-

Conduct regular inspection of various working machineries and vessels

within works areas to avoid any dark smoke emission;

-

Suppress dust generated from work processes with use of bagged cements,

earth movements, excavation activities, exposed surfaces/soil stockpiles and

haul road traffic;

-

Quieter powered mechanical equipment should be used;

-

Provision of proper and effective noise control measures for operating

equipment and machinery on-site, such as erection of movable noise barriers or

enclosure for noisy plants;

-

Closely check and replace the sound insulation materials regularly;

-

Better scheduling of construction works to minimize noise nuisance;

-

Properly store and label oil drums and chemical containers placed on

site;

-

Proper chemicals, chemical wastes and wastes management;

-

Maintenance works should be carried out within roofed, paved and

confined areas;

-

Collection and segregation of construction waste and general refuse on

land and in the sea should be carried out properly and regularly; and

-

Proper protection and regular inspection of existing trees,

transplanted/retained trees.

-

Control night-time lighting and glare by hooding all lights.

-

Regular review and provide maintenance to dust control measures such as

sprinkler system.

1.1.1

Contract No. HY/2010/02 – Hong

Kong-Zhuhai-Macao Bridge Hong Kong Boundary Crossing Facilities – Reclamation

Work (here below, known as “the Project”) mainly comprises reclamation at the

northeast of the

Hong Kong International

Airport of an

area of about

130-hectare for the construction of an artificial island for

the development of the Hong Kong Boundary Crossing Facilities (HKBCF), and

about 19-hectare for the southern landfall of the Tuen Mun - Chek Lap Kok Link

(TMCLKL).

1.1.2

The environmental

impact assessment (EIA)

reports (Hong Kong

– Zhuhai –

Macao Bridge Hong Kong Boundary

Crossing Facilities – EIA Report (Register No. AEIAR-145/2009) (HKBCFEIA) and

Tuen Mun – Chek Lap Kok Link – EIA Report (Register No. AEIAR-146/2009)

(TMCLKLEIA), and their environmental monitoring and audit (EM&A) Manuals

(original EM&A Manuals), for the Project were approved by Environmental

Protection Department (EPD) in October 2009.

1.1.3

EPD subsequently

issued the Environmental

Permit (EP) for HKBCF in November

2009 (EP-353/2009) and the Variation of Environmental Permit (VEP) in June 2010

(EP-353/2009/A), November 2010

(EP-353/2009/B), November

2011 (EP-353/2009/C), March 2012

(EP-353/2009/D), October 2012

(EP-353/2009/E), April 2013 (EP-353/2009/F) and August 2013 (EP-353/2009/G). Similarly, EPD issued the Environmental Permit (EP) for TMCLKL in

November 2009 (EP-354/2009) and the Variation of Environmental Permit (VEP) in

December 2010 (EP-354/2009/A) and January 2014 (EP-354/2009/B).

1.1.4

The Project is a designated

project and is governed by the current permits for the Project, i.e. the

amended EPs issued on 6 August 2013

(EP-353/2009/G) and 28 January 2014

(EP-354/2009/B) (for TMCLKL Southern Landfall Reclamation only).

1.1.5

A Project Specific EM&A

Manual, which included all project-relation contents from the original EM&A

Manuals for the Project, was issued in May 2012.

1.1.6

Ove Arup & Partners Hong

Kong Limited (Arup) was appointed by Highways Department (HyD) as the

consultants for the design and construction assignment for the Project’s

reclamation works (i.e. the Engineer for the Project).

1.1.7

China Harbour Engineering

Company Limited (CHEC) was awarded by HyD as the Contractor to undertake the

construction work of the Project.

1.1.8

ENVIRON Hong Kong Ltd. was

employed by HyD as the Independent Environmental Checker (IEC) and

Environmental Project Office (ENPO) for the Project.

1.1.9

AECOM Asia Co. Ltd. (AECOM) was

appointed by CHEC to undertake the role of Environmental Team for the Project

for carrying out the EM&A works.

1.1.10

The construction phase of the

Project under the EPs was commenced on 12 March 2012 and will be tentatively

completed by early Year 2016.

1.1.11

According to the Project

Specific EM&A Manual, there is a need of an EM&A programme including

air quality, noise, water quality and dolphin monitoring and environmental site

inspections. The EM&A programme of the Project commenced on 12 March 2012.

1.2

Scope of Report

1.2.1

This is the thirty-first

monthly EM&A Report under the Contract

No.HY/2010/02 Hong Kong-Zhuhai-Macao Bridge Hong Kong Boundary Crossing

Facilities – Reclamation Works. This report presents a summary of the

environmental monitoring and audit works, list of activities and mitigation

measures proposed by the ET for the Project in September 2014.

1.3.1 The project organization structure is shown in Appendix A. The key

personnel contact names and numbers are summarized in Table 1.1.

Table

1.1 Contact Information of Key

Personnel

|

Party

|

Position

|

Name

|

Telephone

|

Fax

|

|

Engineer’s Representative (ER)

(Ove

Arup & Partners Hong Kong Limited)

|

Chief Resident Engineer

|

Roger Marechal

|

3698 5700

|

2698 5999

|

|

IEC / ENPO

(ENVIRON Hong Kong Limited)

|

Independent Environmental Checker

|

Raymond Dai

|

3465 2888

|

3465 2899

|

|

Environmental Project Office Leader

|

Y. H. Hui

|

3465 2868

|

3465 2899

|

|

Contractor

(China Harbour Engineering

Company Limited)

|

Environmental Officer

|

Richard Ng

|

36932253

|

2578 0413

|

|

24-hour Hotline

|

Alan C.C. Yeung

|

9448 0325

|

--

|

|

ET

(AECOM

Asia Company Limited)

|

ET Leader

|

Echo Leong

|

3922 9280

|

2317 7609

|

1.4.1 The construction phase of the

Project under the EP commenced on 12 March 2012.

1.4.2 As informed by the Contractor,

details of the major works carried out in this reporting period are listed

below:-

Marine-based Works

-

Cellular structure installation

-

Optimizing rubble mound seawalls

-

Conforming sloping seawalls

-

Laying geo-textile

-

Sand blanket laying

-

Sand filling

-

Rock filling

-

Maintenance of silt curtain & silt screen at sea water intake of

HKIA

-

Band drain installation

-

Backfill cellular structure

-

Geotechnical Instrumentation works

-

Surcharge laying

-

Capping Beams structures

-

Construction of temporary jetties for surcharge laying

-

Temporary Watermain construction

-

Flat barge of unloading public fill for surcharge laying

-

Precast Yard Setup

Land-based Works

-

Maintenance works of Site Office at Works Area WA2

-

Maintenance works of Public Works Regional Laboratory at Works Area

WA3

-

Maintenance of Temporary Marine Access at Works Area WA2

1.4.3 The 3-month rolling construction

programme of the Project is shown in Appendix B.

1.4.4 The general layout plan of the

Project site showing the detailed works areas is shown in Figure 1.

1.4.5 The environmental mitigation

measures implementation schedule are presented in Appendix C.

1.5.1

The EM&A programme required environmental monitoring for air

quality, noise, water quality, marine ecology and environmental site

inspections for air quality, noise, water quality, waste management, marine

ecology, and landscape and visual impact. The EM&A requirements for each

parameter described in the following sections include:-

-

All monitoring parameters;

-

Monitoring schedules for

the reporting month and forthcoming month;

-

Action and Limit levels

for all environmental parameters;

-

Event / Action Plan;

-

Environmental mitigation

measures, as recommended in the Project EIA reports; and

-

Environmental requirement

in contract documents.

2.1.1 In accordance with the Project

Specific EM&A Manual, baseline 1-hour and 24-hour Total Suspended Particulates

(TSP) levels at 4 air quality monitoring stations were established. Impact

1-hour TSP monitoring was conducted for at least three times every 6 days,

while impact 24-hour TSP monitoring was carried out for at least once every 6

days. The Action and Limit level of the air quality monitoring is provided in

Appendix D.

2.2.1 24-hour TSP air quality

monitoring was performed using High Volume Sampler (HVS) located at each

designated monitoring station. The HVS meets all the requirements of the

Project Specific EM&A Manual.

Portable direct reading dust meters were used to carry out the 1-hour

TSP monitoring. Brand and model of the

equipment is given in Table 2.1.

Table 2.1 Air

Quality Monitoring Equipment

|

Equipment

|

Brand and Model

|

|

Portable direct

reading dust meter (1-hour TSP)

|

Sibata Digital

Dust Monitor (Model No. LD-3 and LD-3B)

|

|

High Volume

Sampler

(24-hour TSP)

|

Tisch

Environmental Mass Flow Controlled Total Suspended Particulate (TSP) High Volume

Air Sampler

(Model No.

TE-5170)

|

2.3

Monitoring Locations

2.3.1 Monitoring locations AMS2 and

AMS7 were set up at the proposed locations in accordance with Project Specific

EM&A Manual. For AMS6 (Dragonair/CNAC (Group) Building), permission on

setting up and carrying out impact monitoring works was sought, however, access

to the premise has not been granted yet on this report issuing date. For

monitoring location AMS3 (Ho Yu College), as proposed in the Project Specific

EM&A Manual, approval for carrying out impact monitoring could not be

obtained from the principal of the school. Permission on setting up and

carrying out impact monitoring works at nearby sensitive receivers, like

Caribbean Coast and Coastal Skyline, was also sought. However, approvals for carrying out impact

monitoring works within their premises were not obtained. Impact air quality

monitoring was conducted at site boundary of the site office area in Works Area

WA2 (AMS3B) respectively. Same baseline and Action Level for air quality, as

derived from the baseline monitoring data recorded at Ho Yu College, was

adopted for this alternative air quality location.

2.3.2 It was observed that a tree near

AMS3B may affect the wind flow around the HVS located at AMS3B. With no further

comment received from IEC, the HVS at AMS3B has been relocated on 8 September

2014 to slightly more than 2 meters separation from it, measured

horizontally. Same baseline and Action

Level for air quality, as derived from the baseline monitoring data recorded at

Ho Yu College, was adopted for this alternative air quality location.

2.3.3 Reference is made to ET’s

proposal of the omission

of air monitoring station (AMS 6) dated on 1 November 2012 and EPD’s letter dated on 19 November

2012 regarding the conditional approval of the proposed omission of air monitoring

station (AMS 6) for Contract No. HY/2010/02. The

aforesaid omission of

Monitoring Station AMS6 is effective since 19 November 2012.

2.3.4 Figure 2 shows the locations of

monitoring stations. Table 2.2 describes the details of the monitoring

stations.

Table 2.2 Locations of Impact Air Quality

Monitoring Stations

|

Monitoring Station

|

Location

|

Description

|

|

AMS2

|

Tung

Chung

Development

Pier

|

Rooftop

of the premise

|

|

AMS3B

|

Site

Boundary of Site Office

Area

at Works Area WA2

|

On ground at the area boundary

|

|

AMS6*

|

Dragonair/CNAC (Group) Building

|

On ground at boundary of the premise

|

|

AMS7

|

Hong

Kong SkyCity

Marriott

Hotel

|

On ground at boundary of the premise

|

#Remarks: Reference is made to EPD conditional

approval of the omission of air monitoring station (AMS 6) for the project. The

omission will be effective on 19 November 2012.

2.4

Monitoring Parameters,

Frequency and Duration

2.4.1 Table 2.3 summarizes the monitoring

parameters, frequency and duration of impact TSP monitoring.

Table 2.3 Air

Quality Monitoring Parameters, Frequency and Duration

|

Parameter

|

Frequency and Duration

|

|

1-hour TSP

|

Three times every 6 days while the

highest dust impact was expected

|

|

24-hour TSP

|

Once every 6 days

|

2.5

Monitoring Methodology

2.5.1 24-hour TSP Monitoring

(a)

The HVS was installed in the vicinity of the

air sensitive receivers. The following

criteria were considered in the installation of the HVS.

(i)

A horizontal platform with appropriate

support to secure the sampler against gusty wind was provided.

(ii)

No two samplers should be placed less than 2 meters

apart.

(iii)

The distance between the HVS and any

obstacles, such as buildings, was at least twice the height that the obstacle

protrudes above the HVS.

(iv)

A minimum of 2 meters separation from walls,

parapets and penthouse for rooftop sampler.

(v)

A minimum of 2 meters separation from any supporting

structure, measured horizontally is required.

(vi)

No furnace or incinerator flues nearby.

(vii)

Airflow around the sampler was unrestricted.

(viii)

Permission was obtained to set up the

samplers and access to the monitoring stations.

(ix)

A secured supply of electricity was obtained

to operate the samplers.

(x)

The sampler was located more than 20 meters

from any dripline.

(xi)

Any wire fence and gate, required to protect

the sampler, did not obstruct the monitoring process.

(xii)

Flow control accuracy was kept within ±2.5%

deviation over 24-hour sampling period.

(b)

Preparation of Filter Papers

(i)

Glass fibre filters, G810 were labelled and

sufficient filters that were clean and without pinholes were selected.

(ii)

All filters were equilibrated in the

conditioning environment for 24 hours before weighing. The conditioning

environment temperature was around 25 °C and not variable by more than ±3 °C;

the relative humidity (RH) was < 50% and not variable by more than ±5%. A

convenient working RH was 40%.

(iii)

All filter papers were prepared and analysed

by ALS Technichem (HK) Pty Ltd., which is a HOKLAS accredited laboratory and

has comprehensive quality assurance and quality control programmes.

(c)

Field Monitoring

(i)

The power supply was checked to ensure the

HVS works properly.

(ii)

The filter holder and the area surrounding

the filter were cleaned.

(iii)

The filter holder was removed by loosening

the four bolts and a new filter, with stamped number upward, on a supporting

screen was aligned carefully.

(iv)

The filter was properly aligned on the screen

so that the gasket formed an airtight seal on the outer edges of the filter.

(v)

The swing bolts were fastened to hold the

filter holder down to the frame. The

pressure applied was sufficient to avoid air leakage at the edges.

(vi)

Then the shelter lid was closed and was

secured with the aluminum strip.

(vii)

The HVS was warmed-up for about 5 minutes to

establish run-temperature conditions.

(viii)

A new flow rate record sheet was set into the

flow recorder.

(ix)

On site temperature and atmospheric pressure

readings were taken and the flow rate of the HVS was checked and adjusted at

around 1.1 m3/min, and complied with the range specified in the

updated EM&A Manual (i.e. 0.6-1.7 m3/min).

(x)

The programmable digital timer was set for a

sampling period of 24 hrs, and the starting time, weather condition and the

filter number were recorded.

(xi)

The initial elapsed time was recorded.

(xii)

At the end of sampling, on site temperature

and atmospheric pressure readings were taken and the final flow rate of the HVS

was checked and recorded.

(xiii)

The final elapsed time was recorded.

(xiv)

The sampled filter was removed carefully and

folded in half length so that only surfaces with collected particulate matter

were in contact.

(xv)

It was then placed in a clean plastic

envelope and sealed.

(xvi)

All monitoring information was recorded on a

standard data sheet.

(xvii)

Filters were then sent to ALS Technichem (HK)

Pty Ltd. for analysis.

(d)

Maintenance and Calibration

(i)

The HVS and its accessories were maintained

in good working condition, such as replacing motor brushes routinely and

checking electrical wiring to ensure a continuous power supply.

(ii)

5-point calibration of the HVS was conducted

using TE-5025A Calibration Kit prior to the commencement of baseline

monitoring. Bi-monthly 5-point calibration of the HVS will be carried out

during impact monitoring.

(iii)

Calibration certificate of the HVSs are

provided in Appendix E.

2.5.2 1-hour TSP Monitoring

(a)

Measuring Procedures

The measuring procedures of the 1-hour dust

meter were in accordance with the Manufacturer’s Instruction Manual as

follows:-

(i)

Turn the power on.

(ii)

Close the air collecting opening cover.

(iii)

Push the “TIME SETTING” switch to [BG].

(iv)

Push “START/STOP” switch to perform

background measurement for 6 seconds.

(v)

Turn the knob at SENSI ADJ position to insert

the light scattering plate.

(vi)

Leave the equipment for 1 minute upon “SPAN CHECK”

is indicated in the display.

(vii)

Push “START/STOP” switch to perform automatic

sensitivity adjustment. This measurement takes 1 minute.

(viii)

Pull out the knob and return it to MEASURE

position.

(ix)

Push the “TIME SETTING” switch the time set

in the display to 3 hours.

(x)

Lower down the air collection opening cover.

(xi)

Push “START/STOP” switch to start

measurement.

(b)

Maintenance and Calibration

(i)

The 1-hour TSP meter was calibrated at 1-year

intervals against a continuous particulate TEOM Monitor, Series 1400ab.

Calibration certificates of the Laser Dust Monitors are provided in Appendix E.

(ii)

1-hour validation checking of the TSP meter

against HVS is carried out on half-year basis at the air quality monitoring locations.

2.6

Monitoring Schedule for the

Reporting Month

2.6.1

The schedule for air quality monitoring in September 2014 is provided in Appendix F.

2.7

Results and Observations

2.7.1 The monitoring results for 1-hour

TSP and 24-hour TSP are summarized in Table 2.4 and 2.5 respectively. Detailed impact

air quality monitoring results are presented in Appendix G.

Table 2.4 Summary of 1-hour TSP Monitoring

Results in the Reporting Period

|

|

Average (mg/m3)

|

Range (mg/m3)

|

Action Level (mg/m3)

|

Limit Level (mg/m3)

|

|

AMS2

|

78

|

75 - 82

|

374

|

500

|

|

AMS3B

|

78

|

74 - 81

|

368

|

500

|

|

AMS7

|

78

|

73 - 83

|

370

|

500

|

Table 2.5 Summary of 24-hour TSP Monitoring

Results in the Reporting Period

|

|

Average (mg/m3)

|

Range (mg/m3)

|

Action Level (mg/m3)

|

Limit Level (mg/m3)

|

|

AMS2

|

43

|

20 – 96

|

176

|

260

|

|

AMS3B

|

45

|

26 – 81

|

167

|

260

|

|

AMS7

|

46

|

13 – 68

|

183

|

260

|

2.7.2 All 1-Hour TSP and 24Hr TSP results were below the

Action and Limit Level in the reporting month.

2.7.3 The event action plan is annexed

in Appendix L.

2.7.4 Meteorological information

collected from the wind station during the monitoring periods on the monitoring

dates, as shown in Figure 2, including wind speed and wind direction, is

annexed in Appendix H.

3.1.1 In accordance with the Project

Specific EM&A Manual, impact noise monitoring was conducted for at least

once per week during the construction phase of the Project. The Action and

Limit level of the noise monitoring is provided in Appendix D.

3.2

Monitoring Equipment

3.2.1 Noise monitoring was performed

using sound level meter at each designated monitoring station. The sound level meters deployed comply with

the International Electrotechnical Commission Publications (IEC) 651:1979 (Type

1) and 804:1985 (Type 1) specifications.

Acoustic calibrator was deployed to check the sound level meters at a

known sound pressure level. Brand and

model of the equipment is given in Table 3.1.

Table 3.1 Noise Monitoring Equipment

|

Equipment

|

Brand and Model

|

|

Integrated Sound Level Meter

|

Rion NL-31 &

B&K2238

|

|

Acoustic Calibrator

|

Rion NC-73 & B&K 4231

|

3.3

Monitoring Locations

3.3.1 Monitoring locations NMS2 was set

up at the proposed locations in accordance with Project Specific EM&A

Manual. However, for monitoring location NMS3 (Ho Yu College), as proposed in

the Project Specific EM&A Manual, approval for carrying out impact

monitoring could not be obtained from the principal of the school. Permission

on setting up and carrying out impact monitoring works at nearby sensitive

receivers, like Caribbean Coast and Coastal Skyline, was also sought. However, approvals for carrying out impact

monitoring works within their premises were not obtained. Impact noise

monitoring was conducted at site boundary of the site office area in Works Area

WA2 (NMS3B) respectively. Same baseline noise level (as derived from the

baseline monitoring data recorded at Ho Yu College) and Limit Level were

adopted for this alternative noise monitoring location.

3.3.2 Figure 2 shows the locations of

the monitoring stations. Table 3.2 describes the details of the monitoring

stations.

Table 3.2 Locations

of Impact Noise Monitoring Stations

|

Monitoring Station

|

Location

|

Description

|

|

NMS2

|

Seaview Crescent Tower 1

|

Free-field on the

rooftop of the premise

|

|

NMS3B

|

Site Boundary of Site Office Area at Works Area

WA2

|

Free-field on ground at

the area boundary.

|

3.4.1

Table 3.3 summarizes the monitoring parameters, frequency and duration of

impact noise monitoring.

Table 3.3 Noise Monitoring Parameters, Frequency

and Duration

|

Parameter

|

Frequency

and Duration

|

|

30-mins measurement at each monitoring station between 0700 and 1900

on normal weekdays (Monday to Saturday). Leq, L10 and L90

would be recorded.

|

At least once per week

|

3.5.1 Monitoring Procedure

(a)

The sound level meter was set on a tripod at

a height of 1.2 m above the ground for free-field measurements at NMS2. A correction

of +3 dB(A) shall be made to the free field measurements.

(b)

All measurement

at NMS3B were free field measurements in the reporting

month at NMS3B. A

correction of +3 dB(A) shall be made to the free field measurements.

(c)

The battery condition was checked to ensure

the correct functioning of the meter.

(d)

Parameters such as frequency weighting, the

time weighting and the measurement time were set as follows:-

(i)

frequency weighting: A

(ii)

time weighting: Fast

(iii)

time measurement: Leq(30-minutes)

during non-restricted hours i.e. 07:00 – 1900 on normal weekdays.

(e)

Prior to and after each noise measurement,

the meter was calibrated using the acoustic calibrator for 94dB(A) at 1000

Hz. If the difference in the calibration

level before and after measurement was more than 1 dB(A), the measurement would

be considered invalid and repeat of noise measurement would be required after

re-calibration or repair of the equipment.

(f)

During the monitoring period, the Leq,

L10 and L90 were recorded. In addition, site conditions and noise

sources were recorded on a standard record sheet.

(g)

Noise measurement was paused during periods

of high intrusive noise (e.g. dog barking, helicopter noise) if possible.

Observations were recorded when intrusive noise was unavoidable.

(h)

Noise monitoring was cancelled in the

presence of fog, rain, wind with a steady speed exceeding 5m/s, or wind with

gusts exceeding 10m/s.

The wind speed shall be checked with a portable wind speed meter capable of

measuring the wind speed in m/s.

3.5.2 Maintenance and Calibration

(a)

The microphone head of the sound level meter

was cleaned with soft cloth at regular intervals.

(b)

The meter and calibrator were sent to the

supplier or HOKLAS laboratory to check and calibrate at yearly intervals.

(c)

Calibration certificates of the sound level

meters and acoustic calibrators are provided in Appendix E.

3.6.1 The schedule for construction

noise monitoring in September 2014 is provided in Appendix F.

3.7.1 The monitoring results for

construction noise are summarized in Table 3.4 and the monitoring data is

provided in Appendix I.

Table 3.4 Summary of Construction Noise

Monitoring Results in the Reporting Period

|

|

Average, dB(A),

Leq (30 mins)

|

Range, dB(A),

Leq (30 mins)

|

Limit Level, dB(A),

Leq (30 mins)

|

|

NMS2

|

66

|

66 – 67*

|

75

|

|

NMS3B

|

67

|

65 – 69*

|

70/65^

|

*+3dB(A) Façade correction

included

^

Daytime noise Limit Level of 70 dB(A) applies

to education institutions, while 65dB(A) applies during school examination

period.

3.7.2 No Action or Limit Level Exceedance of

construction noise was recorded in the reporting month.

3.7.3 Major noise sources during the

noise monitoring included construction activities of the Project, construction

activities by other contracts and nearby traffic noise.

3.7.4 The event action plan is annexed

in Appendix L.

4

WATER QUALITY MONITORING

4.1

Monitoring Requirements

4.1.1 Impact water quality monitoring was

carried out to ensure that any deterioration of water quality was detected, and

that timely action was taken to rectify the situation. For impact water quality

monitoring, measurements were taken in accordance with the Project Specific

EM&A Manual. Appendix D shows the established Action/Limit Levels for the

environmental monitoring works.

4.2.1 Table 4.1 summarises the

equipment used in the impact water quality monitoring programme.

Table 4.1 Water Quality Monitoring Equipment

|

Equipment

|

Brand

and Model

|

|

Dissolved

Oxygen (DO) and Temperature Meter, Salinity Meter and Turbidimeter

|

YSI

Model 6820

|

|

pH

Meter

|

YSI

Model 6820 or Thermo Orion 230A+

|

|

Positioning

Equipment

|

JRC

DGPS 224 Model JLR-4341 with J-NAV 500 Model NWZ4551

|

|

Water

Depth Detector

|

Eagle

Cuda-168 and Lowrance x-4

|

|

Water

Sampler

|

Kahlsio

Water Sampler (Vertical) 2.2 L with messenger

|

4.3.1

Table 4.2 summarises the monitoring parameters, frequency and monitoring

depths of impact water quality monitoring as required in the Project Specific

EM&A Manual.

Table

4.2 Impact Water Quality

Monitoring Parameters and Frequency

|

Monitoring

Stations

|

Parameter,

unit

|

Frequency

|

No. of

depth

|

|

Impact Stations:

IS5, IS(Mf)6, IS7, IS8, IS(Mf)9, IS10,

IS(Mf)11, IS(Mf)16, IS17

Control/Far Field

Stations:

CS(Mf)3, CS(Mf)5, CS4, CS6, CSA

Sensitive

Receiver Stations:

SR3-SR7, SR10A&SR10B

|

·

Depth, m

·

Temperature, oC

·

Salinity, ppt

·

Dissolved Oxygen (DO), mg/L

·

DO Saturation, %

·

Turbidity, NTU

·

pH

·

Suspended Solids (SS), mg/L

|

Three times per

week during mid-ebb and mid-flood tides (within ± 1.75 hour of the predicted

time)

|

3

(1 m below water

surface, mid-depth and 1 m above sea bed, except where the water depth is

less than 6 m, in which case the mid-depth station may be omitted.

Should the water depth be less than 3 m, only the mid-depth station will be

monitored).

|

4.4.1 In accordance with the Project

Specific EM&A Manual, twenty-one stations (9 Impact Stations, 7 Sensitive

Receiver Stations and 5 Control/Far Field Stations) were designated for impact

water quality monitoring. The nine Impact Stations (IS) were chosen on the

basis of their proximity to the reclamation and thus the greatest potential for

water quality impacts, the seven Sensitive Receiver Stations (SR) were chosen

as they are close to the key sensitive receives and the five Control/ Far Field

Stations (CS) were chosen to facilitate comparison of the water quality of the

IS stations with less influence by the Project/ ambient water quality

conditions.

4.4.2 Due to safety concern and

topographical condition of the original locations of SR4 and SR10B, alternative

impact water quality monitoring stations, naming as SR4 (N) and SR10B (N), were

adopted, which are situated in vicinity of the original impact water quality

monitoring stations (SR4 and SR10B) and could be reachable.

4.4.3 Same baseline and Action Level for

water quality, as derived from the baseline monitoring data recorded, were

adopted for these alternative impact water quality monitoring stations.

4.4.4 The locations of these monitoring

stations are summarized in Table 4.3 and depicted in Figure 3.

Table

4.3 Impact Water Quality

Monitoring Stations

|

Station

|

Description

|

East

|

North

|

|

IS5

|

Impact Station (Close to HKBCF

construction site)

|

811579

|

817106

|

|

IS(Mf)6

|

Impact Station (Close to HKBCF

construction site)

|

812101

|

817873

|

|

IS7

|

Impact Station (Close to HKBCF

construction site)

|

812244

|

818777

|

|

IS8

|

Impact Station (Close to HKBCF

construction site)

|

814251

|

818412

|

|

IS(Mf)9

|

Impact Station (Close to HKBCF

construction site)

|

813273

|

818850

|

|

IS10

|

Impact Station (Close to HKBCF

construction site)

|

812577

|

820670

|

|

IS(Mf)11

|

Impact Station (Close to HKBCF

construction site)

|

813562

|

820716

|

|

IS(Mf)16

|

Impact Station (Close to HKBCF

construction site)

|

814328

|

819497

|

|

IS17

|

Impact Station (Close to HKBCF

construction site)

|

814539

|

820391

|

|

SR3

|

Sensitive receivers (San Tau SSSI)

|

810525

|

816456

|

|

SR4(N)

|

Sensitive receivers (Tai Ho)

|

814705

|

817859

|

|

SR5

|

Sensitive receivers (Artificial Reef in NE

Airport)

|

811489

|

820455

|

|

SR6

|

Sensitive receivers (Sha Chau and Lung Kwu

Chau Marine Park)

|

805837

|

821818

|

|

SR7

|

Sensitive receivers (Tai Mo Do)

|

814293

|

821431

|

|

SR10A

|

Sensitive receivers (Ma Wan FCZ)1

|

823741

|

823495

|

|

SR10B(N)

|

Sensitive receivers (Ma Wan FCZ)2

|

823683

|

823187

|

|

CS(Mf)3

|

Control Station

|

809989

|

821117

|

|

CS(Mf)5

|

Control Station

|

817990

|

821129

|

|

CS4

|

Control Station

|

810025

|

824004

|

|

CS6

|

Control Station

|

817028

|

823992

|

|

CSA

|

Control Station

|

818103

|

823064

|

4.5.1 Instrumentation

(a)

The in-situ water quality parameters, viz.

dissolved oxygen, temperature, salinity, turbidity and pH, were measured by multi-parameter

meters (i.e. Model YSI 6820 CE-C-M-Y) and pH meter (i.e. Thermo Orion 230A+) respectively.

4.5.2 Operating/Analytical Procedures

(a)

Digital Differential Global Positioning Systems (DGPS) were

used to ensure that the correct location was selected prior to sample

collection.

(b)

Portable, battery-operated echo sounders were

used for the determination of water depth at each designated monitoring

station.

(c)

All in-situ measurements were taken at 3

water depths, 1 m

below water surface, mid-depth and 1 m above sea bed, except where the water

depth was less than 6 m, in which case the mid-depth station was omitted.

Should the water depth be less than 3 m, only the mid-depth station was

monitored.

(d)

At each measurement/sampling depth, two

consecutive in-situ monitoring (DO concentration and saturation, temperature,

turbidity, pH, salinity) and water sample for SS. The probes were retrieved out

of the water after the first measurement and then re-deployed for the second

measurement. Where the difference in the value between the first and second

readings of DO or turbidity parameters was more than 25% of the value of the

first reading, the reading was discarded and further readings were taken.

(e)

Duplicate samples from each independent

sampling event were collected for SS measurement. Water samples were collected

using the water samplers and the samples were stored in high-density polythene

bottles. Water samples collected were well-mixed in the water sampler prior to

pre-rinsing and transferring to sample bottles. Sample bottles were pre-rinsed

with the same water samples. The sample bottles were then be packed in

cool-boxes (cooled at 4oC without being frozen), and delivered to

ALS Technichem (HK) Pty Ltd. for the analysis of suspended solids concentrations.

The laboratory determination work would be started within 24 hours after

collection of the water samples. ALS Technichem

(HK) Pty Ltd. is a HOKLAS accredited laboratory and has comprehensive quality

assurance and quality control programmes. For QA/QC procedures, one duplicate

samples of every batch of 20 samples was analyzed.

(f)

The analysis method and reporting and

detection limit for SS is shown in Table 4.4.

Table 4.4 Laboratory

Analysis for Suspended Solids

|

Parameters

|

Instrumentation

|

Analytical

Method

|

Reporting

Limit

|

Detection

Limit

|

|

Suspended

Solid (SS)

|

Weighting

|

APHA 2540-D

|

0.5mg/L

|

0.5mg/L

|

(g)

Other relevant data were recorded, including

monitoring location / position, time, water depth, tidal stages, weather conditions

and any special phenomena or work underway at the construction site in the

field log sheet for

information.

4.5.3 Maintenance and Calibration

(a)

All in situ monitoring instruments would be

calibrated and calibrated by ALS Technichem (HK) Pty Ltd. before use and at

3-monthly intervals throughout all stages of the water quality monitoring programme. Calibration details

are provided in Appendix E.

(b)

The dissolved oxygen probe of YSI 6820 was

calibrated by wet bulb method. Before the calibration routine, the sensor for

dissolved oxygen was thermally equilibrated in water-saturated air. Calibration

cup is served as a calibration chamber and it was loosened from airtight

condition before it is used for the calibration. Calibration at ALS Technichem

(HK) Pty Ltd. was carried out once every three months in a water sample with a

known concentration of dissolved oxygen. The sensor was immersed in the water

and after thermal equilibration, the known mg/L value was keyed in and the

calibration was carried out automatically.

(c)

The turbidity probe of YSI 6820 is calibrated

two times a month. A zero check in distilled water was performed with the

turbidity probe of YSI 6820 once per monitoring day. The probe will be

calibrated with a solution of known NTU at ALS Technichem (HK) Pty Ltd. once

every three months.

4.6

Monitoring Schedule for the Reporting Month

4.6.1 The schedule for impact water

quality monitoring in September 2014 is provided in Appendix F.

4.6.2 The scheduled water

quality monitoring at mid ebb on 15 September 2014 has been cancelled due

to adverse weather condition.

4.7.1 Impact water quality monitoring

results and graphical presentations are provided in Appendix J.

Table 4.5 Summary

of Water Quality Exceedances

|

Station

|

Exceedance Level

|

DO (S&M)

|

DO (Bottom)

|

Turbidity

|

SS

|

Total

|

|

Ebb

|

Flood

|

Ebb

|

Flood

|

Ebb

|

Flood

|

Ebb

|

Flood

|

Ebb

|

Flood

|

|

IS5

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

(1) 10 Sept 14

|

0

|

1

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS(Mf)6

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS7

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS8

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

(1) 5 Sept 14

|

0

|

1

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS(Mf)9

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS10

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS(Mf)11

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS(Mf)16

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

IS17

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

SR3

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

(1) 10 Sept 14

|

0

|

1

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

SR4(N)

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

SR5

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

SR6

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

SR7

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

1

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

SR10A

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

SR10B

(N)

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

(1) 12 Sept 14

|

0

|

1

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

|

Total

|

Action

|

0

|

0

|

0

|

0

|

0

|

0

|

2

|

2

|

4

|

|

|

Limit

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

0

|

Note: S: Surface; and

M: Mid-depth.

4.7.3

(1) One Action Level Exceedance of SS

(27.4mg/L) was recorded at IS8 during flood tide on 5 September 2014.

4.7.3.1

For marine works, marine filling was conducted at portion E2 during

flood at area behind cellular structures on 5 September 2014. Also refer to

layout map above.

4.7.3.2

Exceedance was not due to marine based construction works of the Project

because:

4.7.3.3

As informed by the Contractor, filling was conducted on 3, 5 and 8

September 2014 at Portion E2, but with referred to monitoring record and photo

record attached, no sediment plume has been observed to flow from the inside of

the perimeter silt curtain to the outside of the perimeter silt curtain and no

discoloration of sea water has been observed.

4.7.3.4

Photo record of sea condition taken during flood tide at north of HKBCF

Reclamation Works near IS8 on 5 September 2014.

4.7.3.5

Construction activities were reviewed, almost the same marine works were

conducted at almost the same location on 3, 5 and 8 September 2014, but no SS exceedance

was recorded on 3 and 8 September 2014. This indicates that the SS exceedance

was unlikely to attribute to marine works of this Contract.

4.7.3.6

IS(Mf)9 and IS(Mf)16 are located closer to the active works than

monitoring station IS8. Depth Averaged Suspended Solids (SS) values (in mg/L)

recorded during the flood tide on the same day at IS(Mf)9 and IS(Mf)16 were

below the Action and Limit Level which shows that the water quality closer to

active works was not adversely affected.

4.7.3.7

The monitoring location of monitoring station IS8 are considered located

upstream to the active works of this project during flood tide. Therefore it

was unlikely that the exceedance recorded at IS8 was due to active construction

activities of this project.

4.7.3.8

Turbidity level (NTU) result recorded on 5 September 2014 at IS8 during

flood tide is 24.5 NTU which is below the Action and Limit Level, this

indicates turbidity level was not adversely affected.

4.7.3.9

The exceedance was likely due to local effects in the vicinity of IS8.

4.7.3.10

For action required under the action plan, refer to EM&A manual of this Contract for

Event and Action Plan for Water Quality.

4.7.3.11

Action taken under the action plan:

1. Not applicable as SS was not measured in

situ;

2. After considering the above mentioned investigation

results, it appears that it was unlikely that the SS exceedance was attributed

to active construction activities of this project;

3. IEC, contractor and ER were informed via email;

4. Monitoring data, all plant, equipment and

Contractor's working methods were checked;

5-7. Since it is considered that the SS exceedance

is unlikely to be project related, as such, actions 5 - 7 under the EAP are not

considered applicable.

4.7.3.12

Nevertheless, the Contractor was

reminded to ensure provision of ongoing maintenance to the silt curtains and to

carry out maintenance work once defects were found.

4.7.3.13 As informed by the Contractor, maintenance work of the silt curtain is

on-going and carried out by the Contractor on a daily basis.

4.7.4

(2) Two

Action Level Exceedances of SS (26mg/L and 32.3mg/L) were recorded at IS5 and

SR3 during ebb tide on 5 September 2014.

4.7.4.1 For marine works, marine filling

was conducted at portion E2 during ebb tide at area behind cellular structures

on 10 September 2014.

4.7.4.2 Exceedances were not due to

marine based construction works of the Project because:

4.7.4.3 As informed by the Contractor,

filling was conducted on 8, 10 and 12 September 2014 at Portion E2, but with

referred to monitoring record and photo record attached, no sediment plume has

been observed to flow from the inside of the perimeter silt curtain to the

outside of the perimeter silt curtain and no discoloration of sea water has

been observed.

4.7.4.4 Photo record of sea condition

taken at South of HKBCF Reclamation Works near IS5 and SR3 on 10 September

2014.

4.7.4.5 Construction activities were

reviewed, almost the same marine works were conducted at almost the same

location on 8, 10 and 12 September 2014, but no SS exceedance was recorded at

IS5 or SR3 on 8 and 12 September 2014. This indicates that the SS exceedances

were unlikely to attribute to marine works of this Contract.

4.7.4.6 IS7 and IS(Mf)6 are located

closer to the active works than monitoring station IS5 and SR3. Depth Averaged

Suspended Solids (SS) values (in mg/L) recorded during the ebb tide on the same

day at IS7 and IS(Mf)6 were below the Action and Limit Level which shows that the

water quality closer to active works was not adversely affected. Therefore it

was unlikely that the SS exceedances recorded at IS5 and SR3 were due to active

construction activities of this project.

4.7.4.7 Turbidity level (NTU) result

recorded on 10 September 2014 at IS5 and SR3 during ebb tide are 22.3 NTU and

23.9 NTU respectively which are below the Action and Limit Level, this

indicates turbidity level was not adversely affected.

4.7.4.8 The exceedances were likely due

to local effects in the vicinity of IS5 and SR3.

4.7.4.9 Action taken under the action

plan:

1. Not applicable as SS was not measured in situ;

2. After considering the above mentioned investigation results, it

appears that it was unlikely that the SS exceedances were attributed to active

construction activities of this project;

3. IEC, contractor and ER were informed via email;

4. Monitoring data, all plant, equipment and Contractor's working

methods were checked;

5-7. Since it is considered that the SS exceedances are unlikely to be

project related, as such, actions 5 - 7 under the EAP are not considered

applicable.

4.7.4.10

Nevertheless, the Contractor was reminded to ensure provision of ongoing

maintenance to the silt curtains and to carry out maintenance work once defects

were found.

4.7.4.11

As informed by the Contractor, maintenance work of the silt curtain is

on-going and carried out by the Contractor on a daily basis.

4.7.5

(1) One

Action Level Exceedance of SS (24.5mg/L) was recorded at IS10B(N) during ebb

tide on 12 September 2014.

4.7.5.1 For marine works, marine filling was conducted

at portion E2 during flood at area behind cellular structures on 12 September

2014. Also refer to layout map attached.

4.7.5.2 Exceedance was not due to marine based

construction works of the Project because:

4.7.5.3 IS(Mf)11 and IS10 are located downstream and

closer to the active works than monitoring station SR10B(N) during flood tide.

Depth Averaged Suspended Solids (SS) values (in mg/L) recorded during flood tide on the same day at IS(Mf)11 and

IS10 were below the Action and Limit Level which indicates project work is

unlikely to contribute to the action level exceedance recorded at SR10B(N).

4.7.5.4 The monitoring location of monitoring station

SR10B(N) are considered upstream and remote to the active works of this project

during flood tide. Therefore it was unlikely that the exceedance recorded at

SR10B(N) during flood tide was due to active construction activities of this

project.

4.7.5.5 The exceedance was likely due to local effects

in the vicinity of SR10B(N).

4.7.5.6 Action taken under the action plan:

1. Not applicable as SS was not measured in

situ;

2. After considering the above mentioned

investigation results, it appears that it was unlikely that the SS exceedance

was attributed to active construction activities of this project;

3. IEC, contractor and ER were informed via email;

4. Monitoring data, all plant, equipment and

Contractor's working methods were checked;

5-7. Since it is considered that the SS exceedance

is unlikely to be project related, as such, actions 5 - 7 under the EAP are not

considered applicable.

4.7.5.7 Nevertheless, the Contractor was reminded to

ensure provision of ongoing maintenance to the silt curtains and to carry out

maintenance work once defects were found.

4.7.5.8 As informed by the Contractor, maintenance work

of the silt curtain is on-going and carried out by the Contractor on a daily

basis.

4.7.6

The event action plan is annexed in

Appendix L.

5

Dolphin monitoring

5.1.1 Vessel based surveys for the

Chinese White Dolphin (CWD), Sousa

chinensis, are to be conducted by a dedicated team comprising a qualified

marine mammal ecologist and experienced marine mammal observers (MMOs). The

purpose of the surveys are to evaluate the impact of the HKCBF reclamation and,

if deemed detrimental, to take appropriate action as per the EM&A manual.

5.1.2 This ‘Impact Monitoring’ follows

several months of ‘Baseline Monitoring’ so similar survey methodologies have

been adopted to facilitate comparisons between datasets. Further, the data collected are compatible

with, and are available for, incorporation into the data set managed by the

Agriculture, Fisheries and Conservation Department (AFCD) as part of Hong

Kong’s long term Marine Mammal Monitoring Programme.

5.2.1 Table 5.1 summarises the equipment

used for the impact dolphin monitoring.

Table 5.1 Dolphin Monitoring Equipment

|

Equipment

|

Model

|

|

Commercially licensed motor vessel

|

15m in

length with a 4.5m viewing platform

|

|

Global Positioning

System (GPS) x2

|

Integrated

into T7000

Garmin

GPS Map 76C

|

|

Computers

(T7000 Tablet, Intel Atom)

|

Windows

7/MSO 13

Logger

|

|

Camera

|

Nikon

D7100 300m 2.8D fixed focus

Nikon

D90 80-400mm zoom lens

|

|

Laser

Rangefinder

|

Range

Finder Bushnell 1000m

|

|

Marine

Binocular x3

|

Nexus

7 x 50 marine binocular with compass and reticules

Fujinon 7 x 50 marine binocular

with compass and reticules

|

5.3.1 Dolphin monitoring is conducted

twice per month in each survey area.

5.3.2 Dolphin monitoring is conducted only

when visibility is good (e.g., over 1km) and the sea condition is at a Beaufort

Sea State of 4 or better.

5.3.3 When thunder storm, black rain or

typhoon warnings are in force, all survey effort is stopped.

5.4.1 The impact dolphin monitoring is

vessel-based and combines line-transect and photo-ID methodology. The survey follows pre-set and fixed transect

lines in the two areas defined by AFCD as:

5.4.2

Northeast Lantau survey area; and

5.4.3

Northwest Lantau survey area.

5.4.4 The co-ordinates for the transect

lines and layout map have been provided by AFCD and are shown in Table 5.2 and

Figure 4.

Table 5.2 Impact Dolphin Monitoring Line

Transect Co-ordinates (Provided by AFCD)

|

|

HK Grid System

|

Long Lat in WGS84

|

|

ID

|

X

|

Y

|

Long

|

Lat

|

|

1

|

804671

|

814577

|

113.870308

|

22.269741

|

|

1

|

804671

|

831404

|

113.869975

|

22.421696

|

|

2

|

805475

|

815457

|

113.878087

|

22.277704

|

|

2

|

805477

|

826654

|

113.877896

|

22.378814

|

|

3

|

806464

|

819435

|

113.887615

|

22.313643

|

|

3

|

806464

|

822911

|

113.887550

|

22.345030

|

|

4

|

807518

|

819771

|

113.897833

|

22.316697

|

|

4

|

807518

|

829230

|

113.897663

|

22.402113

|

|

5

|

808504

|

820220

|

113.907397

|

22.320761

|

|

5

|

808504

|

828602

|

113.907252

|

22.396462

|

|

6

|

809490

|

820466

|

113.916965

|

22.323003

|

|

6

|

809490

|

825352

|

113.916884

|

22.367128

|

|

7

|

810499

|

820690

|

113.926752

|

22.325043

|

|

7

|

810499

|

824613

|

113.926688

|

22.360464

|

|

8

|

811508

|

820847

|

113.936539

|

22.326475

|

|

8

|

811508

|

824254

|

113.936486

|

22.357241

|

|

9

|

812516

|

820892

|

113.946329

|

22.326894

|

|

9

|

812516

|

824254

|

113.946279

|

22.357255

|

|

10*

|

813525

|

818270

|

113.956156

|

22.303225

|

|

10*

|

813525

|

824657

|

113.956065

|

22.360912

|

|

11

|

814556

|

818449

|

113.966160

|

22.304858

|

|

11

|

814556

|

820992

|

113.966125

|

22.327820

|

|

12

|

815542

|

818807

|

113.975726

|

22.308109

|

|

12

|

815542

|

824882

|

113.975647

|

22.362962

|

|

13

|

816506

|

819480

|

113.985072

|

22.314192

|

|

13

|

816506

|

824859

|

113.985005

|

22.362771

|

|

14

|

817537

|

820220

|

113.995070

|

22.320883

|

|

14

|

817537

|

824613

|

113.995018

|

22.360556

|

|

15

|

818568

|

820735

|

114.005071

|

22.325550

|

|

15

|

818568

|

824433

|

114.005030

|

22.358947

|

|

16

|

819532

|

821420

|

114.014420

|

22.331747

|

|

16

|

819532

|

824209

|

114.014390

|

22.356933

|

|

17

|

820451

|

822125

|

114.023333

|

22.338117

|

|

17

|

820451

|

823671

|

114.023317

|

22.352084

|

|

18

|

821504

|

822371

|

114.033556

|

22.340353

|

|

18

|

821504

|

823761

|

114.033544

|

22.352903

|

|

19

|

822513

|

823268

|

114.043340

|

22.348458

|

|

19

|

822513

|

824321

|

114.043331

|

22.357971

|

|

20

|

823477

|

823402

|

114.052695

|

22.349680

|

|

20

|

823477

|

824613

|

114.052686

|

22.360610

|

|

21

|

805476

|

827081

|

113.877878

|

22.382668

|

|

21

|

805476

|

830562

|

113.877811

|

22.414103

|

|

22

|

806464

|

824033

|

113.887520

|

22.355164

|

|

22

|

806464

|

829598

|

113.887416

|

22.405423

|

|

23

|

814559

|

821739

|

113.966142

|

22.334574

|

|

23

|

814559

|

824768

|

113.966101

|

22.361920

|

*Remark: Due to the presence of deployed

silt curtain systems at the site boundaries of the Project, some of the

transect lines shown in Figure 5 could not be fully surveyed during the regular

survey. Transect 10 is reduced from 6.4km to approximately 3.6km in length due

to the HKBCF construction site. Therefore the total transect length for both

NEL and NWL combined is reduced to approximately 111km.

5.5.1 The study area incorporates 23

transects which are to be surveyed twice per month. Each survey day lasts approximately 9

hours.

5.5.2 The survey vessel departs from

Tung Chung Development Pier, Tsing Yi Public Pier or the nearest safe and

convenient pier.

5.5.3 When the vessel reaches the start

of a transect line, “on effort” survey begins. Areas between transect lines and

traveling to and from the study area are defined as “off effort”.

5.5.4 The transect line is surveyed at

a speed of 6-8 knots (11-14 km/hr). For the sake of safety, the speed was

sometimes a bit slower to avoid collision with other vessels. During some periods, tide and current flow in

the survey areas exceeds 7 knots which can affect survey speed. There are a

minimum of four marine mammal observers (MMOs) present on each survey, rotating

through four positions, observers (2), data recorder (1) and ‘rest’ (1). Rotations

occur every 30 minutes or at the end of dolphin encounters. The data recorder records effort, weather and

sightings data directly onto the programme Logger and is not

part of the observer team. The observers search with naked

eye and binoculars between 90° and 270° abeam (bow being 0°).

5.5.5 When a group of dolphins is

sighted, position, bearing and distance data are recorded immediately onto the

computer and, after a short observation, an estimate made of group size. These parameters are linked to the

time-GPS-ships data which are automatically stored in the programme Logger

throughout the survey period. In this

manner, information on heading, position, speed, weather, effort and sightings

are stored in a format suitable for use with DISTANCE software for subsequent

line transect analyses.

5.5.6 Once the vessel leaves the

transect line, it is deemed to be “off effort”. The dolphins are approached

with the purpose of taking high resolution pictures for proper photo-identification

of individual CWD. Attempts to

photograph all dolphins in the group are made.

Both the left and right hand sides of the dorsal fin area of each

dolphin in the group are photographed, if possible. On finishing photographing, the vessel will

return to the transect line at the point of departure and “on effort” survey is

resumed.

5.5.7 Sightings which are made while on

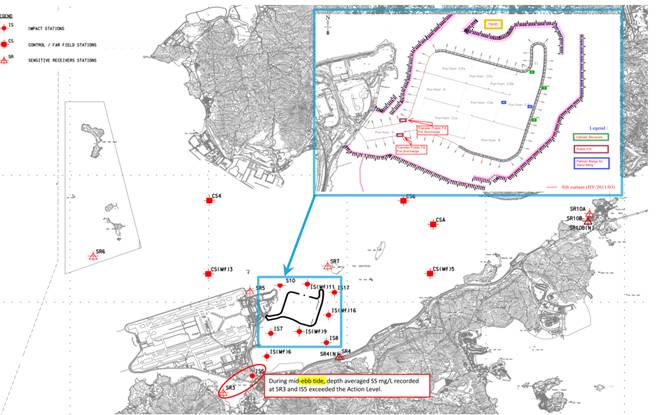

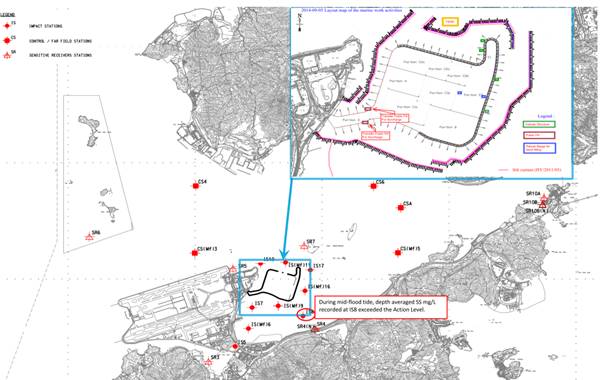

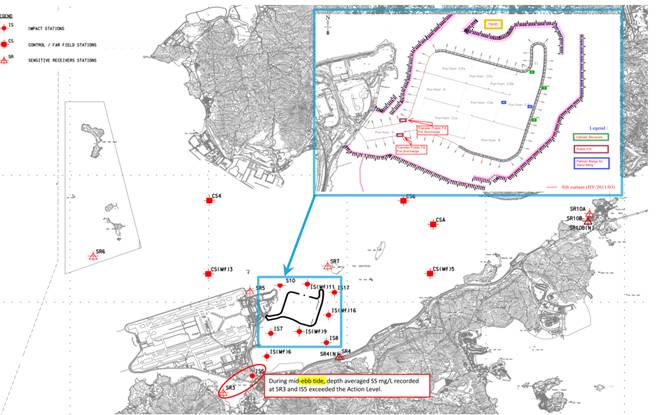

the transect line are referred to as "on effort sightings", while not