Executive Summary

1 Introduction

1.1 Background

1.2 Scope of Report

1.3 Organization Structure

1.4 Summary of Construction Works

2 EM&A Results

2.1 Air quality

2.2 Landfill Gas Hazard

Monitoring

2.3 EM&A Site Inspection

2.4 Waste Management Status

2.5 Environmental Licenses and

Permits

2.6 Implementation Status of

Environmental Mitigation Measures

2.7 Summary of Exceedances of the

Environmental Quality Performance Limit

2.8 Summary of Complaints,

Notification of Summons and Successful Prosecutions

3 Future Key Issues

3.1 Construction Activities for

the Coming Month

3.2 Key Issues for the Coming

Month

4 Conclusions and recommendations

4.1 Conclusions

List of Appendices

Appendix A Project Organization for Environmental Works

Appendix B Three

Month Rolling Construction Programmes

Appendix C Implementation

Schedule of Environmental Mitigation Measures (EMIS)

Appendix D Summary

of Action and Limit Levels

Appendix E Event

Action Plan

Appendix F Monthly

Summary of Waste Flow Table

Appendix

G Cumulative Statistics on Exceedances, Complaints,

Notifications of Summons and Successful Prosecutions

Executive

Summary

Under Contract

No. HY/2017/10, Gammon Construction Limited (GCL) is commissioned by the

Highways Department (HyD) to undertake Northern Connection Tunnel Buildings,

Electrical and Mechanical Works of the Tuen Mun – Chek Lap Kok Link Project (TM-CLK

Link Project) while AECOM Asia Company Limited was appointed by HyD as the

Engineer. For implementation of the

environmental monitoring and audit (EM&A) programme under the Contract, ERM-Hong

Kong, Limited (ERM) has been appointed as the Environmental Team (ET) in

accordance with Environmental Permit No.

EP-354/2009/A. Ramboll Hong Kong Ltd. was employed by HyD as

the Independent Environmental Checker (IEC) and Environmental Project Office

(ENPO). Subsequent

applications for variation of environmental permits (VEP), EP-354/2009/B, EP-354/2009/C and

EP-354/2009/D, were granted on 28

January 2014, 10 December 2014 and 13 March 2015, respectively.

The construction phase of the Project commenced on 7

June 2018 and will tentatively be completed by 2021. The impact monitoring of the EM&A

programme, including air quality and environmental site inspections, were commenced

on 7 June 2018. In addition, landfill

gas monitoring shall be carried out for the Project in accordance with

the Updated EM&A Manual for TM-CLK Link Project (Agreement No. CE 52/2007).

This is the First Monthly EM&A report presenting

the EM&A works carried out during the period from 7 to 30 June 2018 for the

Contract No. HY/2017/10 Northern Connection Tunnel

Buildings, Electrical and Mechanical Works

(the “Project”) in accordance with the Updated EM&A Manual of the

TM-CLK Link Project. As informed by the Contractor, major

activities in the reporting period included:

Land-based Works

·

Bar bending and timber formwork at Toll Control Building

and Ventilation Plant Room;

·

ER’s and the Contractor’s site offices erection at

WA18; and

·

Additional land ground investigation (GI) at

Administration Building, trial pits and laboratory testing.

A summary of monitoring and audit activities conducted

in the reporting period is listed below:

24-hour TSP Monitoring 8

sessions

1-hour TSP Monitoring 8

sessions

Joint Environmental Site Inspection 4 sessions

Summary of Breaches of Action/Limit Levels

Breaches of

Action and Limit Levels for Air Quality

No exceedance of 1-hour and 24-hour TSP was recorded in

this reporting month.

Environmental Complaints, Non-compliance & Summons

There was no environmental complaint, notification of

summons or successful prosecution recorded in the reporting period.

Reporting Change

There was no reporting change in the reporting period.

Upcoming Works for the Next Reporting Month

Works to be undertaken in the next monitoring period of

July 2018 include the following:

Land-based Works

·

Bar bending and timber formwork at Toll Control

Building and Ventilation Plant Room;

·

ER’s and the Contractor’s site offices erection at

WA18; and

·

Socket H-pilling at Administration Building.

Future Key

Issues

Potential environmental impacts arising from the above

upcoming construction activities in the next reporting month of July 2018 are

mainly associated with dust and waste management issues.

1

Introduction

According to the findings of the Northwest New

Territories (NWNT) Traffic and Infrastructure Review conducted by the Transport

Department, Tuen Mun Road, Ting Kau Bridge, Lantau Link and North Lantau

Highway would be operating beyond capacity after 2016. This forecast has been based on the estimated

increase in cross boundary traffic, developments in the Northwest New Territories

(NWNT), and possible developments in North Lantau, including the Airport

developments, the Lantau Logistics Park (LLP) and the Hong Kong – Zhuhai –

Macao Bridge (HZMB). In order to cope

with the anticipated traffic demand, two new road sections between NWNT and

North Lantau – Tuen Mun – Chek Lap Kok Link (TM-CLKL) and Tuen Mun Western

Bypass (TMWB) are proposed.

An Environmental Impact Assessment (EIA) of TM-CLKL (the

Project) was prepared in accordance with the EIA Study Brief (No. ESB-175/2007)

and the Technical Memorandum of the

Environmental Impact Assessment Process (EIAO-TM). The EIA Report was

submitted under the Environmental Impact Assessment Ordinance (EIAO) in August

2009. Subsequent to the approval of the

EIA Report (EIAO Register Number AEIAR-146/2009), an Environmental Permit

(EP-354/2009) for TM-CLKL was granted by the Director of Environmental

Protection (DEP) on 4 November 2009, and EP variation (VEP) (EP-354/2009/A) was

issued on 8 December 2010. Subsequent

applications for variation of environmental permits (VEPs), EP-354/2009/B, EP-354/2009/C and EP-354/2009/D, were granted on 28

January 2014, 10 December 2014 and 13 March 2015, respectively.

Under Contract

No. HY/2017/10, Gammon Construction Limited (GCL) is commissioned by the

Highways Department (HyD) to undertake the Northern Connection Tunnel

Buildings, Electrical and Mechanical Works of TM-CLKL while AECOM

Asia Company Limited was appointed by HyD as the Engineer. For implementation of the environmental

monitoring and audit (EM&A) programme under the Contract, ERM-Hong Kong,

Limited (ERM) has been appointed as the Environmental Team (ET). Ramboll Hong

Kong Ltd. was employed by HyD as the Independent Environmental Checker (IEC)

and Environmental Project Office (ENPO).

The construction phase of the Contract commenced on 7

June 2018 and will be tentatively completed by 2021. The impact monitoring phase of the EM&A

programme, including air quality and environmental site inspections, commenced

on 7 June 2018.

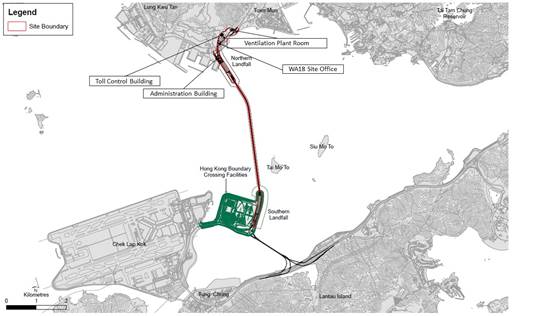

The general layout plan of the Contract components is

presented in Figures 1.1 & 1.2a to c.

This is the First

Monthly EM&A Report under the Contract No.

HY/2017/10 Tuen Mun – Chek Lap Kok Link – Northern Connection Tunnel Buildings,

Electrical and Mechanical Works. This report presents a summary of the

environmental monitoring and audit works in June 2018.

1.3

Organization Structure

The organization structure of the Contract is shown in

Appendix A. The

key personnel contact names and contact details are summarized in Table 1.1 below.

Table 1.1 Contact Information of Key Personnel

|

Party

|

Position

|

Name

|

Telephone

|

Fax

|

|

HyD (Highways

Department)

|

Project

Coordinator

|

Joseph Lee

|

2762 4958

|

3188 6614

|

|

|

Senior

Engineer

|

Cheng Pan

|

2762 3383

|

3188 6614

|

|

ER

(AECOM Asia

Company Limited)

|

Principle

Resident Engineer

|

S. W. Fok

|

2293 6200

|

2293 6300

|

|

|

Resident

Engineer

|

Desmond Fung

|

2293 6200

|

2293 6300

|

|

ENPO / IEC

(Ramboll Hong Kong Ltd.)

|

ENPO Leader

|

Y.H. Hui

|

3465

2850

|

3465 2899

|

|

IEC

|

Dr. F.C. Tsang

|

3465

2851

|

3465 2899

|

|

Contractor

(Gammon

Construction Limited)

|

Site Agent

|

Kenneth Tai

|

9039 4723

|

-

|

|

Environmental

Officer

|

Max Poon

|

9103 6303

|

-

|

|

|

|

|

|

|

|

ET (ERM-HK)

|

ET Leader

|

Dr. Jasmine Ng

|

2271 3311

|

2723 5660

|

The construction phase of the Contract commenced on 7

June 2018. The three-month rolling

construction programme is shown in Appendix B.

As informed by the Contractor, details of the major

works carried out in this reporting month are listed below:

Land-based Works

·

Bar bending and timber formwork at Toll Control

Building and Ventilation Plant Room;

·

ER’s and the Contractor’s site offices erection at

WA18; and

·

Additional land ground investigation (GI) at

Administration Building, trial pits and laboratory testing.

The

locations of the construction activities are shown in Figure 1.3.

The Environmental Sensitive Receivers in the vicinity of the Project are

shown in Figure 1.4.

The

implementation schedule of environmental mitigation measures is presented in Appendix

C.

Figure 1.3 Locations of Major Construction Activities in the

Reporting Month

2

EM&A

Results

The EM&A programme required environmental

monitoring for air quality and environmental site inspections for air quality, water

quality and waste management. The

EM&A requirements and related findings for each component are summarized in

the following sections

2.1.1

Monitoring Requirements and Equipment

In accordance with the Updated EM&A Manual and the

Enhanced TSP Monitoring Plan, impact 1-hour TSP monitoring was conducted three

(3) times every six (6) days and impact 24-hour TSP monitoring was carried out once

every six (6) days when the highest dust impact was expected. 1-hr and 24-hr TSP monitoring frequency was

increased to three times per day every three days and daily every three days,

respectively, as excavation works for launching shaft under Contract No. HY/2012/08 Tuen Mun-Chek Lap

Kok Link – Northern Connection Sub-sea Tunnel Section commenced on 24

October 2014.

Results of air quality monitoring were adopted from

the published EM&A data of Contract

No. HY/2012/08 Tuen Mun-Chek Lap Kok Link – Northern Connection Sub-sea Tunnel

Section ().

The Action and Limit Levels of the air quality

monitoring were adopted from

the published EM&A reports of Contract No. HY/2012/08 Tuen Mun-Chek Lap Kok Link –

Northern Connection Sub-sea Tunnel Section (). The Action and

Limit Levels are provided in Appendix D.

The locations of the monitoring stations overlapped

with Contract

No. HY/2012/08 are shown in Figure

2.1

and presented in Table 2.1.

Table

2.1 Locations of Impact Air Quality Monitoring Stations and and

its Corresponding Monitoring Requirements

|

Monitoring Station

|

Monitoring Dates

|

Location

|

Description

|

Parameters

& Frequency

|

|

ASR1

|

9,

12, 15, 18, 21, 24, 27 and 30 June 2018

|

Tuen

Mun Fireboat Station

|

Office

|

TSP monitoring

Ÿ 1-hour Total Suspended Particulates (1-hour TSP, µg/m3), 3

times in every 6 days

Ÿ 24-hour Total Suspended Particulates (24-hour TSP, µg/m3),

daily for 24-hour in every 6 days

Enhanced TSP monitoring

(commenced on 24 October 2014 under

Contract No. HY/2012/08)

Ÿ 1-hour Total Suspended Particulates (1-hour TSP, µg/m3), 3

times in every 3 days

Ÿ 24-hour Total Suspended Particulates (24-hour TSP, µg/m3),

daily for 24-hour in every 3 days

|

|

ASR5

|

|

Pillar

Point Fire Station

|

Office

|

|

AQMS1

|

|

Previous

River Trade Golf

|

Bare

ground

|

|

ASR6

|

|

Butterfly

Beach Laundry

|

Office

|

|

ASR10

|

|

Butterfly

Beach Park

|

Recreational

uses

|

2.1.2 Monitoring

Methodology

High Volume Sampler

(a) The

HVS was installed in the vicinity of the air sensitive receivers. The following criteria were considered in the

installation of the HVS:

· A

horizontal platform with appropriate support to secure the sampler against gusty

wind was provided.

· The

distance between the HVS and an obstacle, such as buildings, was at least twice the height

that the obstacle protrudes above the sampler.

·

A

minimum of 2m of separation from walls, parapets and penthouses was required

for rooftop samples.

·

A

minimum of 2m separation from any supporting structure, measured horizontally

was required.

·

No

furnaces or incineration flues were nearby.

·

Airflow

around the sampler was unrestricted.

·

The

samplers were more than 20m from the drip line.

·

Any

wire fence and gate, to protect the sampler, should not cause any obstruction

during monitoring.

·

Permission must be obtained to set up the samples

and to obtain access to the monitoring stations.

·

A secured supply of electricity is needed to

operate the samplers.

·

No two samplers should be placed less than 2 m

apart.

(b)

Preparation of Filter Papers

· Filter

papers of size 8”x 10” that were clean and without pinholes were selected.

· All

filter papers were conditioned in a humidity controlled chamber for over 24-hour

and be pre-weighed before use for sampling.

· All

filter papers were prepared and analysed by ALS Technichem (HK) Pty Ltd., which

is a HOKLAS accredited laboratory and has comprehensive quality assurance and

quality control programmes.

(c)

Field Monitoring

· The

power supply was checked to ensure the HVS works properly.

· The

filter holder and the area surrounding the filter were cleaned.

· The

filter holder was removed by loosening the four bolts and a new filter, with

stamped number upward, on a supporting screen was aligned carefully.

· The

filter was properly aligned on the screen so that the gasket formed an airtight

seal on the outer edges of the filter.

· The

swing bolts were fastened to hold the filter holder down to the frame. The pressure applied was sufficient to avoid

air leakage at the edges.

· Then

the shelter lid was closed and was secured with the aluminum strip.

· The

HVS was warmed up for about 5 minutes to establish run-temperature conditions.

· A new

flow rate record sheet was set into the flow recorder.

· On

site temperature and atmospheric pressure readings were taken and the flow rate

of the HVS was checked and adjusted at around 1.1 m3/min, and

complied with the range specified in the Updated EM&A Manual (i.e. 0.6 –

1.7 m3/min).

· The

programmable digital timer was set for a sampling period of 1 hour or 24 hours,

and the starting time, weather condition and the filter number were recorded.

· The

initial elapsed time was recorded.

· At

the end of sampling, on site temperature and atmospheric pressure readings were

taken and the final flow rate of the HVS was checked and recorded.

· The

final elapsed time was recorded.

· The

sampled filter was removed carefully and folded in half-length so that only

surfaces with collected particulate matter were in contact.

· It

was then placed in a clean plastic envelop and sealed.

· All

monitoring information was recorded on a standard data sheet.

· Filters

were then sent to ALS Technichem (HK) Pty Ltd. for analysis.

(d) Maintenance

and Calibration

· The

HVS and its accessories were maintained.

Appropriate

maintenance such as routine motor brushes replacement and electrical wiring

checking were made to ensure that the equipment and necessary power supply are

in good working condition.

· All

HVS were calibrated

(five point calibration) using Calibration Kit prior to the

commencement of the baseline monitoring and thereafter at bi-monthly intervals.

2.1.3 Results

and Observations

Results of air

quality monitoring were adopted from the published EM&A data of Contract No. HY/2012/08 Tuen Mun-Chek Lap Kok Link –

Northern Connection Sub-sea Tunnel Section ().

Neither Action nor Limit Levels exceedances was

recorded by the Environmental Team of Contract No. HY/2012/08 during the reporting period. No action is thus required to be undertaken

in accordance with the Event Action Plan presented in Appendix E.

2.2

Landfill

Gas Hazard Monitoring

2.2.1 Monitoring

Requirements and Equipment

In accordance

with the Updated EM&A Manual, regular landfill gas monitoring shall be

carried out during the excavation and confined area within the landfill

zone of Pillar Point Valley (PPV) Landfill. A Safety

Officer shall be appointed to carry out regular landfill gas hazard monitoring

works during all excavations, manholes, chambers, relocation of monitoring

wells and any other confined spaces that may have been created. All measurements in excavations shall be made

with the extended monitoring tube located not more than 10mm from the exposed

ground surface to ensure that the construction work area is free of landfill

gas before any worker enters in the area.

The Action and Limit Levels of the landfill gas hazard monitoring is

provided in Appendix

D.

The location of the monitoring station is shown in Table

2.2.

Table

2.2 Location of Landfill Gas Monitoring Station

and and its Corresponding Monitoring Requirements

|

Monitoring Station

|

Monitoring Dates

|

Parameters

|

Measurements

& Frequency

|

|

Toll

Control Building

|

To

be implemented in July

|

Ÿ

Oxygen

Ÿ

Methane

Ÿ

Carbon dioxide

|

For excavations deeper

than 1m, measurements should be undertaken

Ÿ At the ground surface before excavation commences;

Ÿ Immedately before any worker enters the excavation;

Ÿ At the beginning of each working date for the entire period the

excavation remains open; and

Ÿ Periodically through the working day whilst workers are in the

excavation

For excavations between

300mm and 1m deep, measurements should be undertaken

Ÿ Directly after the excavation has been completed; and

Ÿ Periodically whilst the excavation remains open

For excavations less than

300mm deep, monitoring works may be omitted, at the discretion of the Safety

Officer or other qualified person

|

|

|

|

|

|

|

|

|

|

|

|

|

2.2.2

Results and Observations

Informed by the

Safety Officer, no landfill gas hazard monitoring was undertaken in the

reporting period in view of the construction works at toll control

building. Event Action Plan is presented

in Appendix

E.

2.3

EM&A

Site Inspection

Site inspections were carried out on a weekly basis to

monitor the implementation of proper environmental pollution control and mitigation

measures under the Contract. In the

reporting month, four (4) site inspections were carried out on 8, 15, 22 and 29

June 2018.

Key observations and recommendations during the site

inspections in this reporting period are summarized in Table 2.2.

Table 2.3 Specific Observations and

Recommendations during the Weekly Site Inspection in this Reporting Month

|

Inspection Date

|

Observations

|

Recommendations/ Remarks

|

|

8 June 2018

|

Ventilation

Plant Room

Ÿ Chemical

containers were observed not placed in drip tray.

Toll

Control Building

Ÿ Stagnant

water in the drip tray near the generator was observed not cleared.

|

Ventilation

Plant Room

Ÿ The

Contractor was reminded to place chemical containers in drip tray.

Toll

Control Building

Ÿ The

Contractor was reminded to clear stagnant water in the drip tray.

|

|

15

June 2018

|

WA18

Ÿ Stagnant

water in the drip tray and trolley in front of site office were observed not

cleared.

Ventilation

Plant Room

Ÿ Chemical

containers were observed not placed in drip tray.

Ÿ Duplicate

QPME label should be displayed on the sides of the generator for checking.

|

WA18

Ÿ The

Contractor was reminded to clear stagnant water in the drip tray and in the

trolley.

Ventilation

Plant Room

Ÿ The

Contractor was reminded to place chemical containers in drip tray.

Ÿ The

Contractor was reminded to provide QPME label on the sides of the generator.

|

|

22

June 2018

|

Toll

Control Building

Ÿ Checklist

should be provided on the wetsep.

Ÿ On-site

sorting should be implemented on site for wastes.

Administration

Building

Ÿ Chemical

labels should be displayed on the chemical containers used in wetsep

operation.

|

Toll

Control Building

Ÿ The

Contractor was reminded to provide wetsep checklist.

Ÿ The

Contractor was reminded to implement on-site waste sorting.

Administration

Building

Ÿ The

Contractor was reminded to provide chemical labels on the checmical

containers.

|

|

29

June 2018

|

Ventilation

Plant Room

Ÿ Stagnant

water in the drip tray was observed not cleared.

Toll

Control Building

Ÿ Chemical

container was observed not placed in drip tray.

|

Ventilation

Plant Room

Ÿ The

Contractor was reminded to clear stagnant water in the drip tray.

Toll

Control Building

Ÿ The

Contractor was reminded to place chemical container in drip tray.

|

The Contractor has rectified all of the observations

as identified during environmental site inspections in the reporting month.

The Contractor had submitted application form for

registration as chemical waste producer under the Contract. Sufficient numbers of receptacles were

available for general refuse collection and sorting.

Wastes generated during this reporting period included

mainly construction wastes (inert and non-inert). Reference has been made to the waste flow

table prepared by the Contractor (Appendix F). The quantities of different types of wastes

are summarized in Table 2.3.

Table 2.4 Quantities of Different Waste Generated

in the Reporting Month

|

Month/Year

|

Inert C&D Materials (a)

(m3)

|

Inert Construction Waste Re-used

(m3)

|

Non-inert Construction Waste (b)

(kg)

|

Imported

Fill (m3)

|

Recyclable Materials (c) (kg)

|

Chemical Wastes (kg)

|

|

|

|

June 2018

|

2085

|

0

|

3,750

|

0

|

0

|

|

0

|

|

|

|

Notes:

|

|

|

|

(a) Inert

construction wastes include hard rock and large broken concrete, and

materials disposed as public fill.

(b) Non-inert

construction wastes include general refuse disposed at landfill.

(c) Recyclable

materials include metals, paper, cardboard, plastics, timber and others.

|

|

|

|

|

|

|

|

|

|

|

|

The Contractor was advised to properly maintain on

site C&D materials and waste collection, sorting and recording system,

dispose of C&D materials and wastes at designated ground and maximize

reuse/ recycle of C&D materials and wastes.

The Contractor was also reminded to properly maintain the site tidiness

and dispose of the wastes accumulated on site regularly and properly.

For chemical waste

containers, the Contractor was reminded to treat properly and store temporarily

in designated chemical waste storage area on site in accordance with the Code of Practice on the Packaging, Labelling

and Storage of Chemical Wastes.

The status of

environmental licensing and permit is summarized in Table 2.4 below.

In response to the site audit findings, the

Contractors carried out all corrective actions.

A summary of the Implementation Schedule of

Environmental Mitigation Measures (EMIS) is presented in Appendix C. The

necessary mitigation measures relevant to this Contract were implemented

properly.

No exceedance of 1-hour and 24-hour TSP was recorded in

this reporting month.

Cumulative statistics are provided in Appendix G.

The Environmental Complaint Handling Procedure is provided in Figure 2.2.

There was no environmental complaint, notification of

summons or successful prosecution recorded in the reporting period.

Statistics on complaints, notifications of summons,

successful prosecutions are summarized in Appendix G.

3

Future

Key Issues

As informed by the Contractor, the major works for the

Project in July 2018 will be:

Land-based Works

·

Bar bending and timber formwork at Toll Control

Building and Ventilation Plant Room;

·

ER’s and the Contractor’s site offices erection at

WA18; and

·

Socket H-pilling at Administration Building.

Potential environmental impacts arising from the above

upcoming construction activities in the next reporting month of July 2018 are

mainly associated with dust and waste management issues.

4

Conclusions

and recommendations

This First Monthly EM&A Report presents the findings of the EM&A

activities undertaken during the period from 7 to 30 June 2018, in accordance

with the Updated EM&A Manual and the requirements of EP-354/2009/D.

Air quality (including 1-hour TSP and 24-hour TSP) was

carried out in this reporting month.

No exceedance of 1-hour and 24-hour TSP was recorded in

this reporting month.

Environmental site inspection was carried out four (4)

times in June 2018. Remedial

actions recommended for the deficiencies identified during the site audits were

properly implemented by the Contractor.

There was no environmental complaint, notification of

summons or successful prosecution recorded in the reporting period.

The ET will keep track on the construction works to

confirm compliance of environmental requirements and the proper implementation

of all necessary mitigation measures.