Contract

No. HY/2011/03

Hong Kong-Zhuhai-Macao Bridge Hong Kong Link

Road

Section between Scenic Hill and Hong Kong Boundary Crossing

Facilities

Acoustic Decoupling Measures Plan

12 September 2012

Main Contractor Designer

![]()

![]()

Contents

2 Acoustic

Decoupling Measures Plan

2.1 Marine Construction Noise Sources

2.2 Proposed Acoustic Decoupling Measures

Appendices

Appendix A:

Photos of Proposed Working Vessel

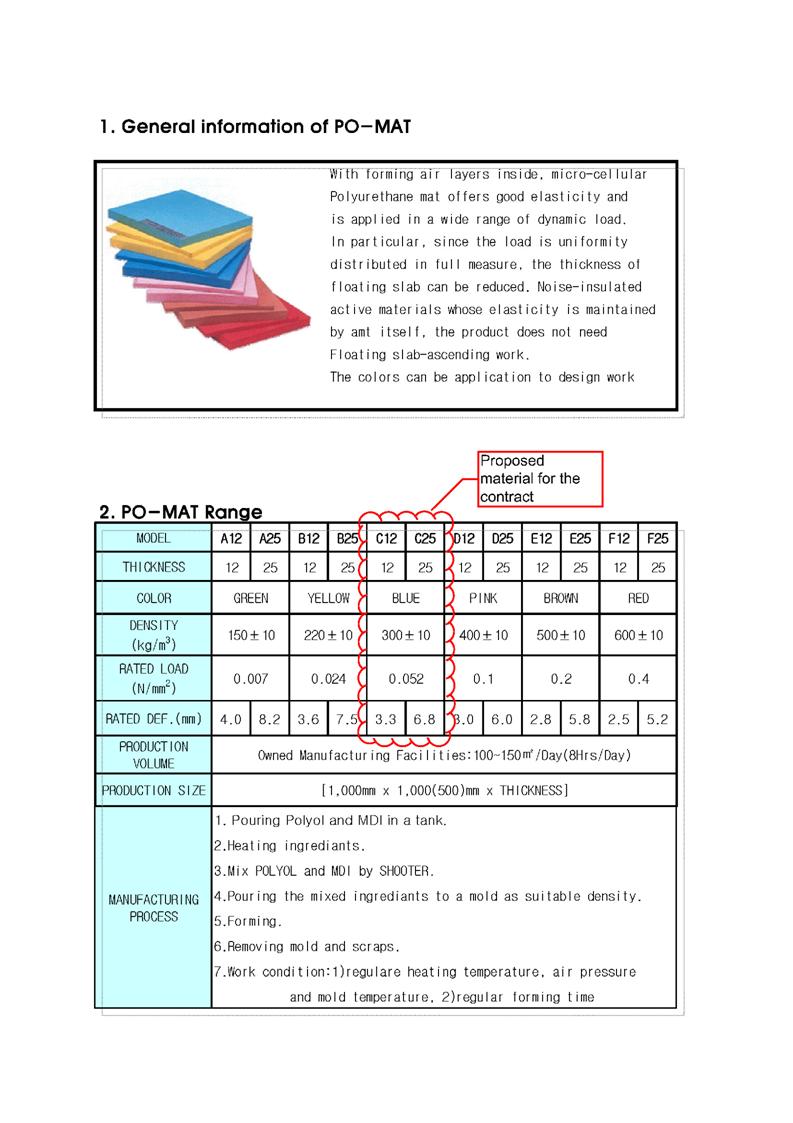

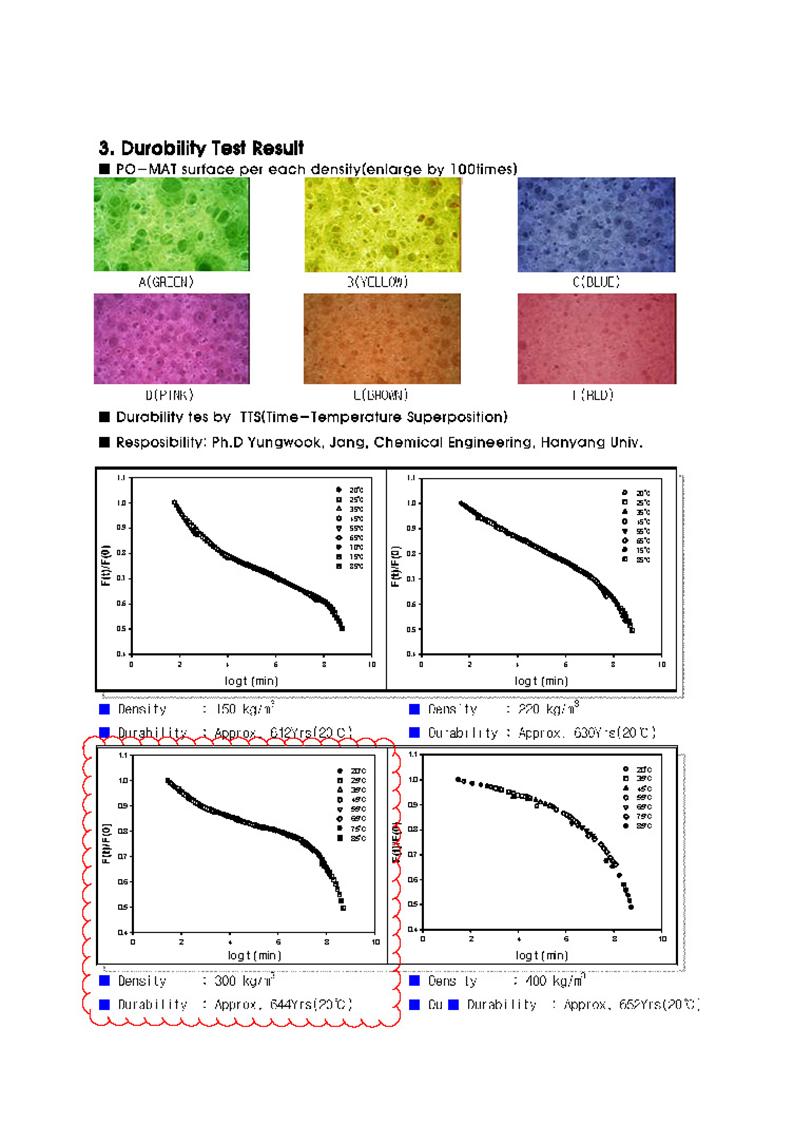

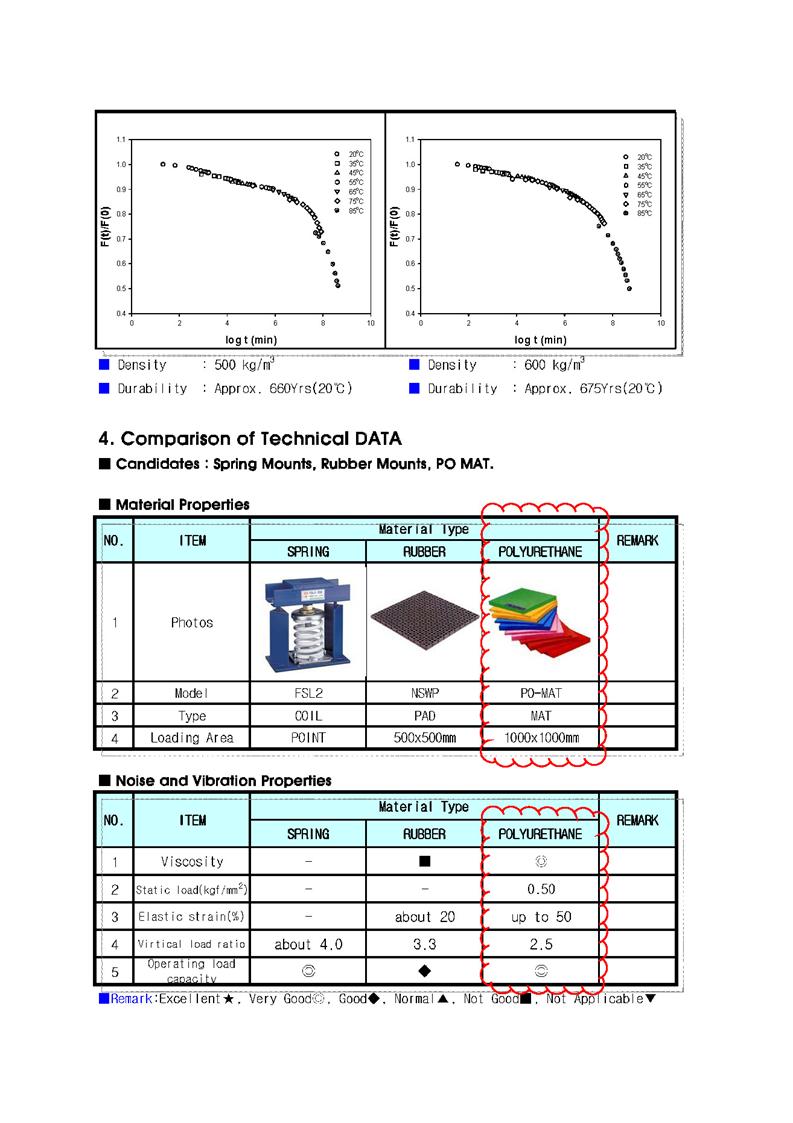

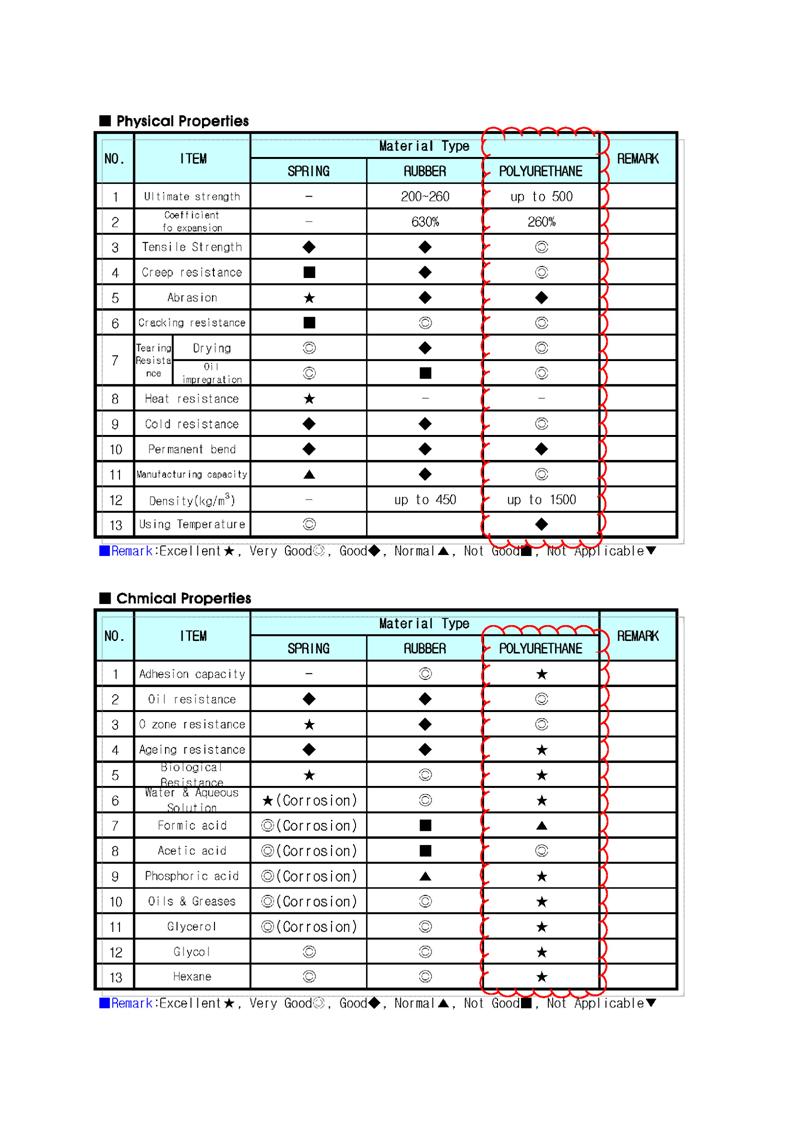

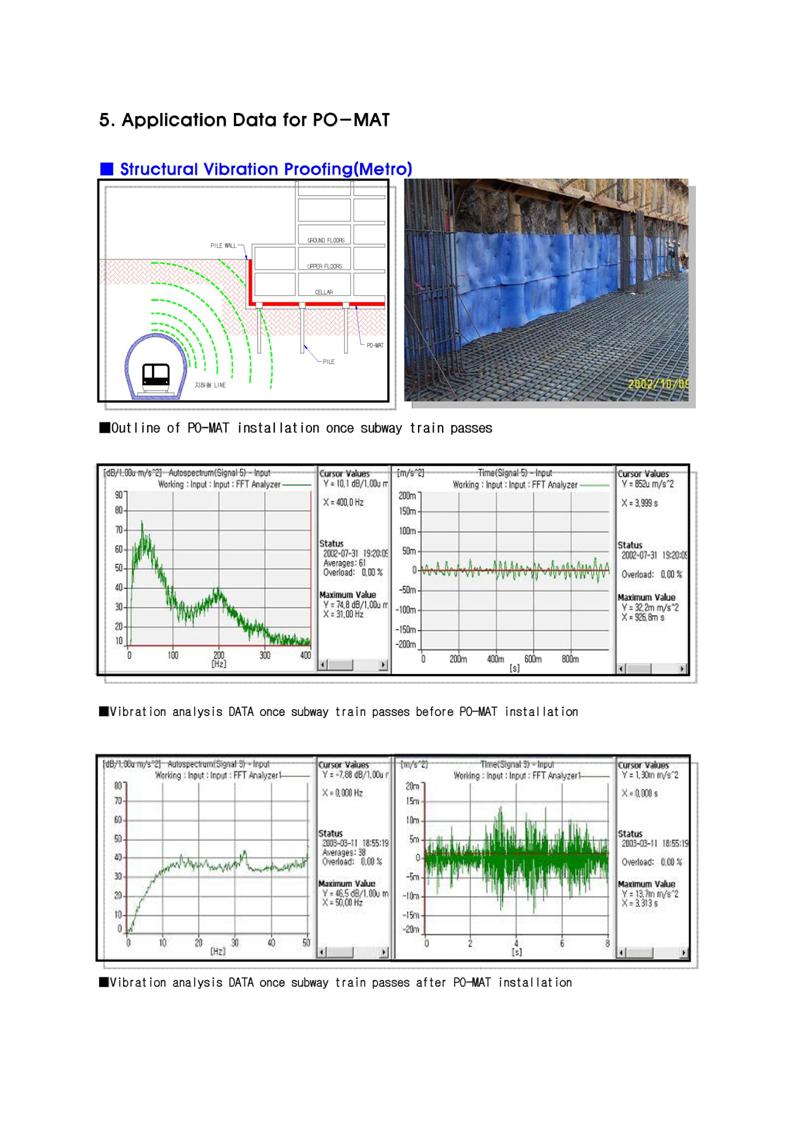

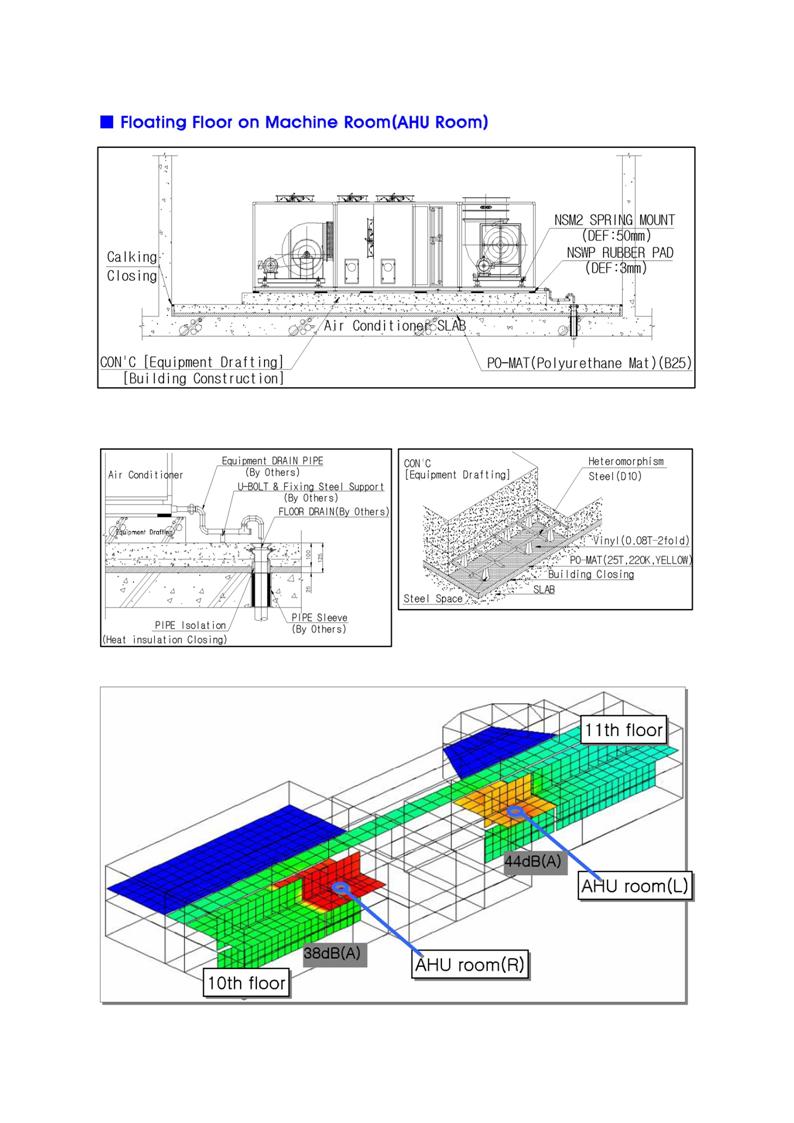

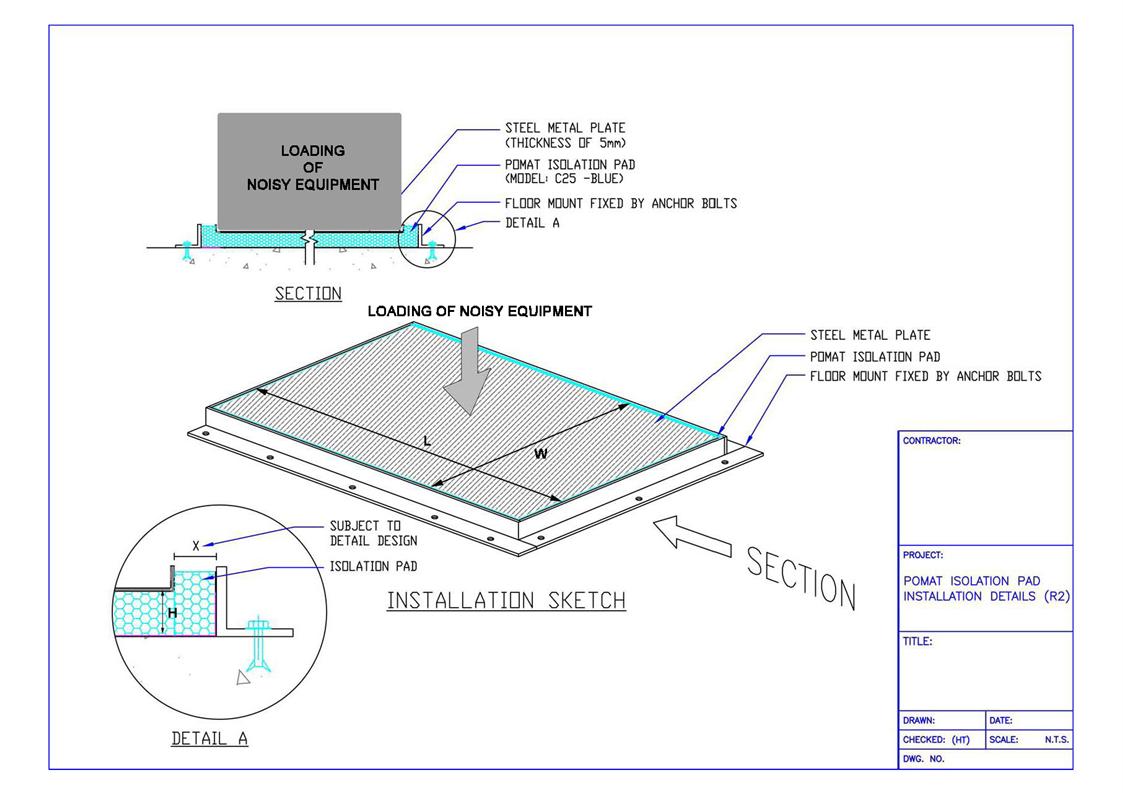

Appendix B: Proposed Isolation Pad Details

Drawings

Drawing 4809-RC-2001 Reclamation

Plan (Sheet 1 of 2)

Drawing 4809-RC-2002 Reclamation

Plan (Sheet 2 of 2)