Contract HY/2010/02

SPILL RESPONSE PLAN

|

|

Name |

Signature |

|

Prepared

By: |

China

Harbour Engineering Company Limited |

|

Table of Content

1 Introduction

2 General Precautions

3 Transfer and Transport Precautions

4 General response to the spill

4.1 Spill

contained on the deck of a vessel or on land

4.2 Spill into the

Marine Environment

4.3 Spillage

Control Material

4.4 Inventory

of hazardous chemicals / compounds

4.5 Protection

of sensitive receivers

5 General dolphin contingency plan for petroleum/chemical spill event

5.1 Initial Action

5.2 All reasonable attempts must be made to keep dolphins away from

contaminated areas

6 Safety Equipment

7 Implementation of the Spill Response Plan

7.1 Notification to workers and frontier workforces

7.2 Training - workers and frontier workforces

7.3 Location of Spill Kits

8 Contact of Relevant Parties

9 Role and Responsibilities of Management Parties

9.1 Emergency Team Leader - General Manager (S & E)

9.2 Safety

Manager (SM)

9.3 Construction

Managers (CM)

9.4 Environmental

Officer (EO)

9.5 Environmental

Supervisor (ES)

9.6 Superintendents

/ Senior Foremen / Foremen

9.7 Workers

10 Notification the relevant parties

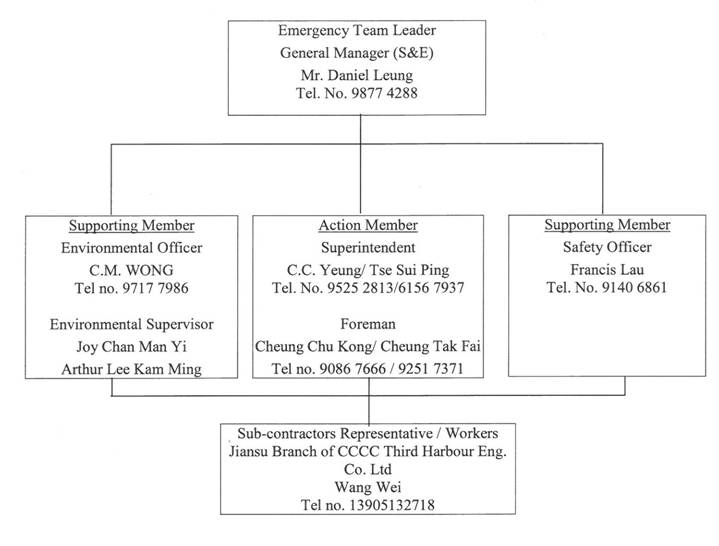

11 Emergency Team Organization

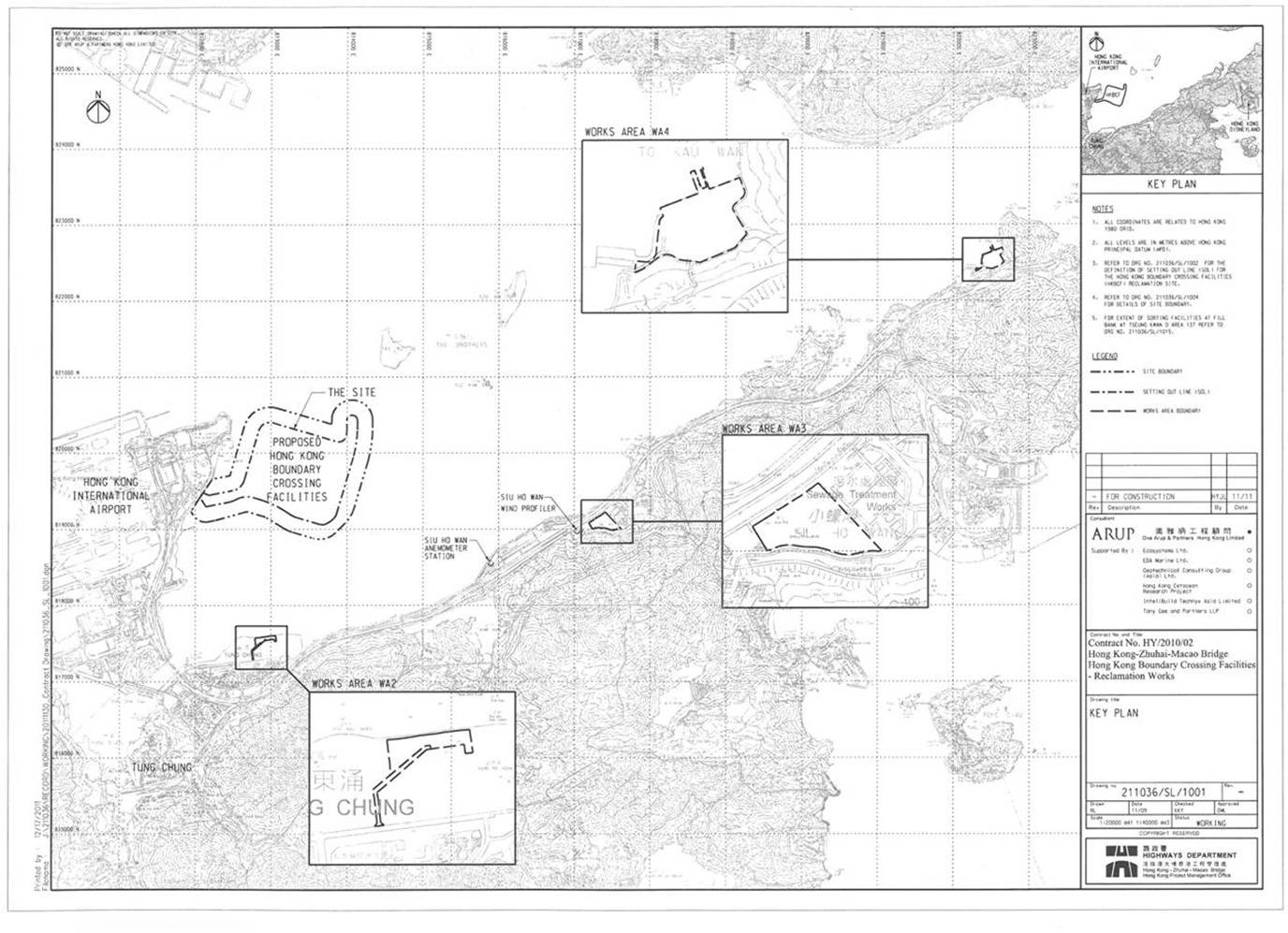

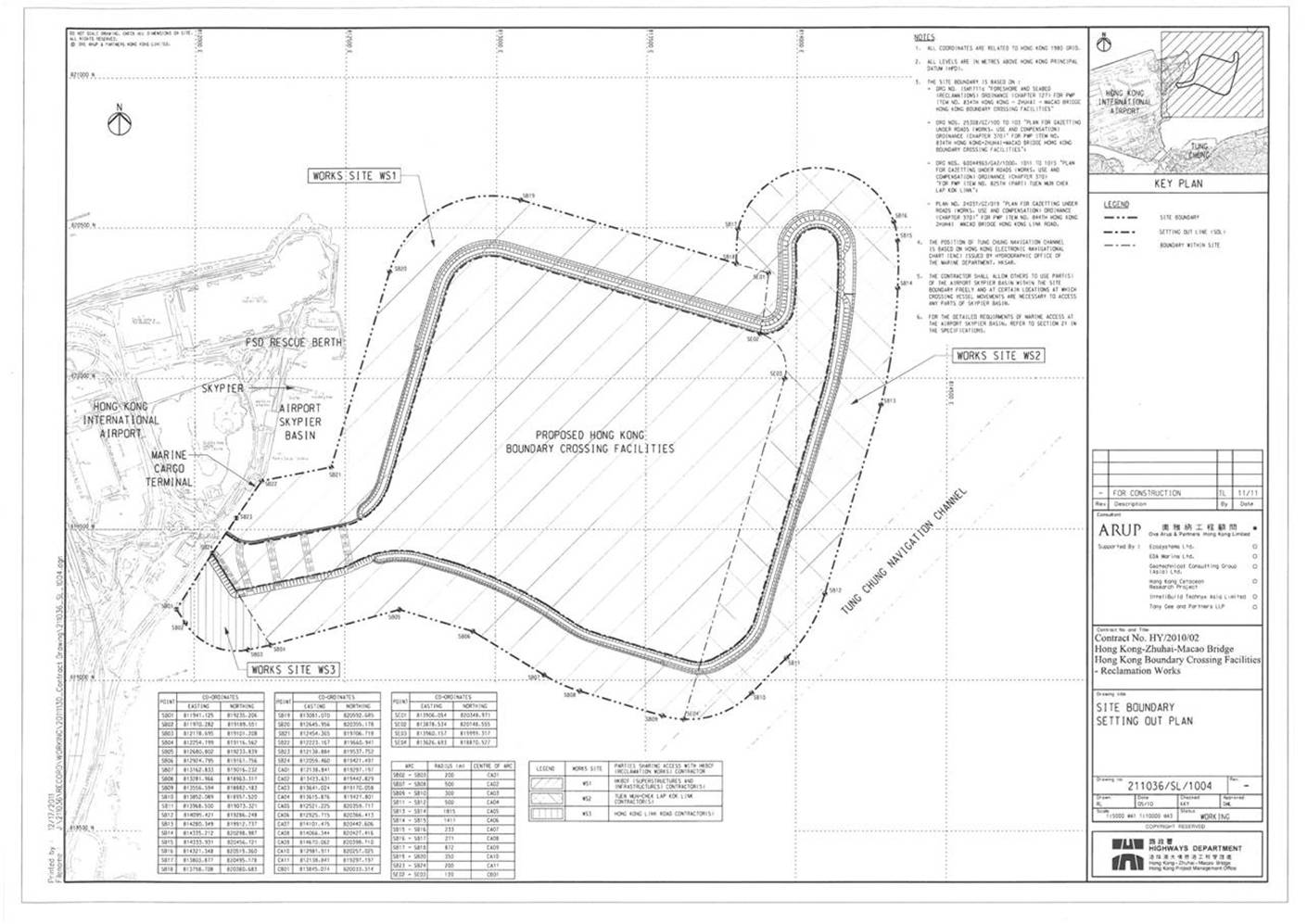

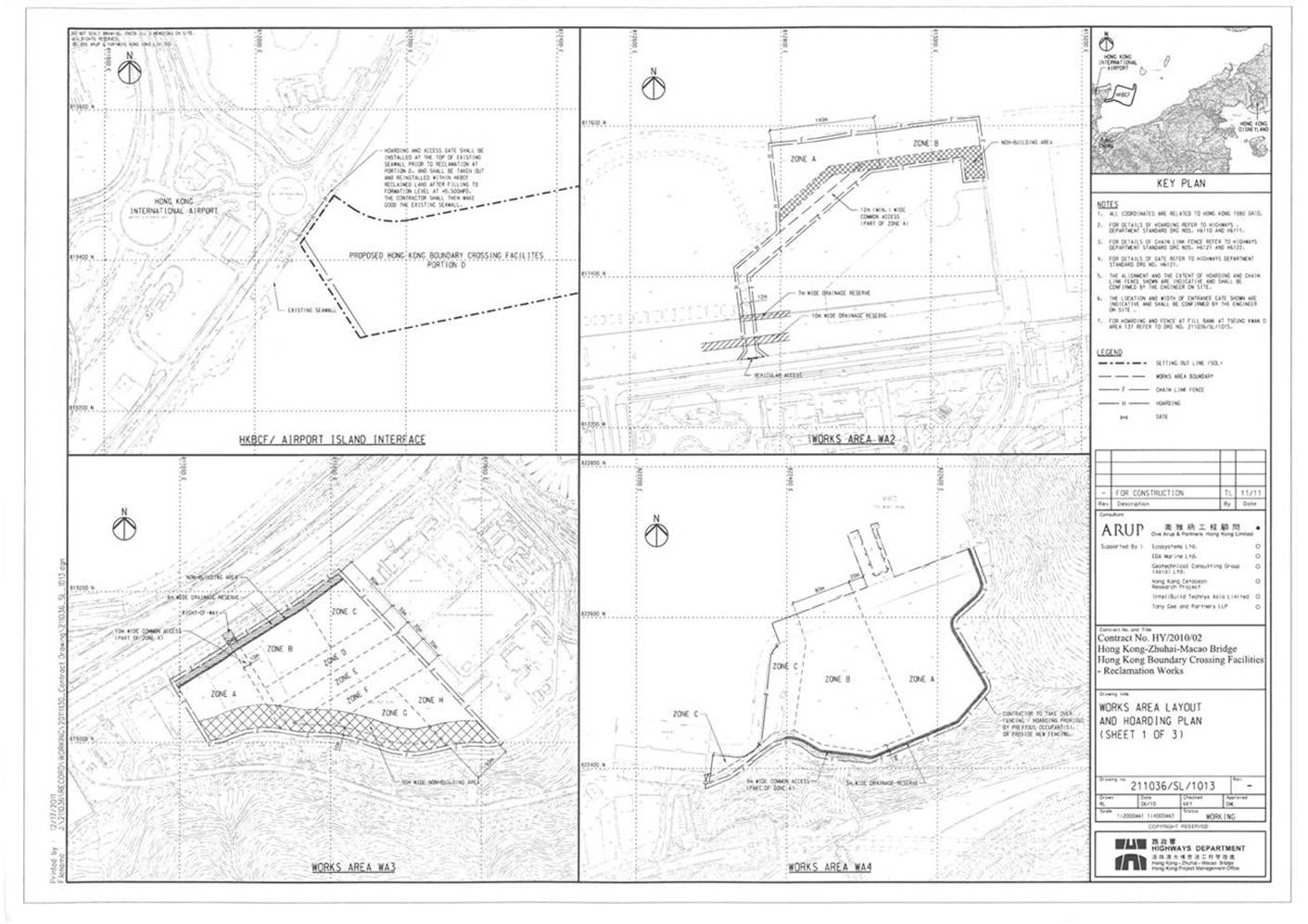

Appendix

A General

Layout of the Site Area

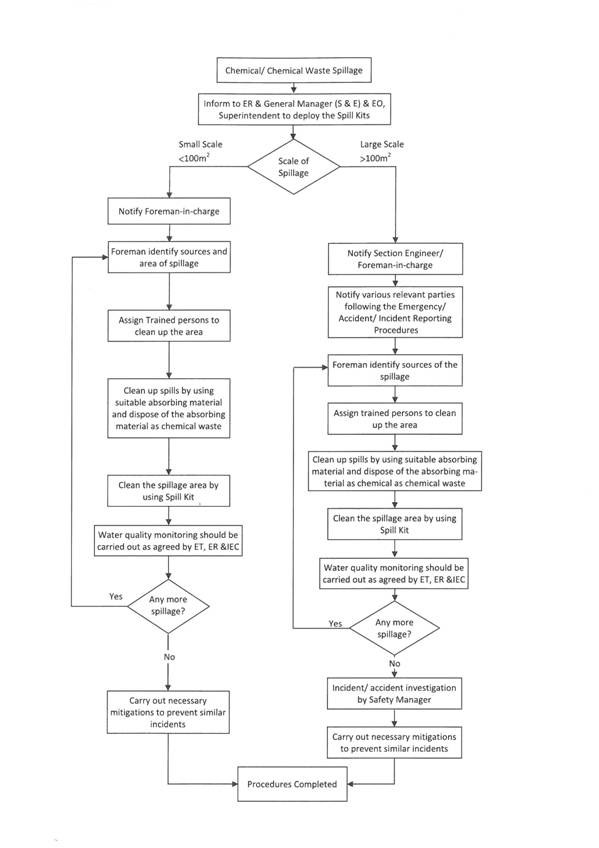

B Flow

Diagram of Handling the Spillage on Site

C Information

of Spill Kits

1.

Introduction

CHEC (China Harbour Engineering Company Limited, hereafter CHEC) are the Main Contractor responsible for the execution of the reclamation works for the Hong Kong-Zhuhai-Macao Bridge (HZMB) - Boundary Crossing Facilities (HKBCF) - Reclamation Works. These works primarily involve the forming of 150 hectares of land area.

The following Spill Response Plan is required under Section 2.7 of Environmental Permit No. EP-353/2009/C and Section 2.7 of Environmental Permit No. EP-354/2009/A. Noting: the Spill Response Plan must be submitted to EPD specifically;

�� the Spill Response Plan detailing the actions to be taken in the event of accidental spillage �K. with specific provisions for protecting marine ecology and the Chinese White Dolphin.��

2. General Precautions

In order to minimize the possibilities of accidental spillage of oil or

other hazardous chemicals at the construction site, the following

precautionary measures will be implemented on site as far as possible:

i) Use drip trays for storage containers of chemical oil fuel tanks and / or generators.

ii) Reduce the danger of stacked containers of oil or chemicals falling.

iii) Provide tightly closed lids so as to avoid leakage of chemicals and chemical waste especially if accidentally knocked over.

iv) Store compatible chemicals and the waste in the same storage area.

v) Inspect the storage area regularly to detect if any leakage has occurred or if any of the containers become defective on a regular weekly basis.

vi) Use suitable containers, which are resistant to the stored chemicals or the chemical waste so as to prevent leakage.

vii) Label the storage containers and the chemical tanks correctly.

viii) Provide adequate ventilation in the storage area as necessary.

ix) Prohibit open flames and smoking near the chemical storage and fuel storage areas.

x) Store large and heavy containers on the floor as far as possible and avoid storing these containers higher than 0.75m above the floor level (storage in vessel / barges are exclusive).

xi) Keep all chemical, chemical waste and fuel oil storage containers below eye level for easy inspection.

xii) Provide adequate space for safe and easy handling and inspection of the containers.

xiii) Maintain an up-to-date log of all chemicals, chemical waste and fuel oil stored at site.

xiv) Separate incompatible chemicals from one another.

xv) Keep the ingress to the chemical storage area locked and restrict access.

xvi) Provide a bucket of dry sand and a suitable fire extinguisher in the storage area.

3.

Transfer and Transport

Precautions

In order to minimize the change of accidental spillage occurring during the transportation of chemicals or containers of chemicals to and from the construction site, some precautionary measures will be implemented on site. These precautions are subject to site conditions and constraints. These are:

i) Use a suitably sized container so as to avoid overfilling.

ii) Use pumps to transfer chemical waste instead of manually pouring them.

iii) Provide a containment structure able to hold any chemical or chemical waste that is accidentally spilled.

iv) Use proper, safe and suitably labeled containers.

v) Use suitable carrying equipment to transfer the chemical and chemical; waste containers from one location to another.

vi) Only employ and use suitably licensed, trained and responsible chemical waste collection persons to carry out the transportation requirements.

4. General response to the spill

The general response to the spill shall be carried out to minimize

the amount of oil or hazardous

chemicals to the marine environment. The location of the spill is also a

consideration. The general response includes the following:

4.1 Spill

contained on the deck of a vessel or on land

Workers should be made aware of the emergency telephone numbers, locations of emergency showers, location of Spill Kits and emergency evacuation routes. Medical emergency response should also be undertaken whenever necessary. The response actions to an incident should include the following steps:

i) Immediately inform the Emergency Team of the spill incident occurring.

ii) Take all possible measures to reduce or stop the spillage, such as shut off the valve.

iii) Provided it is safe to do so, the area containing the spill shall have forced ventilation installed in order to make a safe spillage condition.

iv) The Emergency Team Leader shall be responsible for organizing the manpower to identify the spill source and stop or cease it.

v) The Emergency Team Leader as the assigned person shall equip all people involved in the cleanup works suitable personal protective equipment prior to the removal of any leaked chemical or chemical waste.

vi) If possible and practical, the spilt chemical shall be put back into the containers of origin. Otherwise a suitable material like dry sand or sawdust shall be used to absorb the leakage.

vii) Any contaminated sand / sawdust / other materials shall be collected and put into black plastic bags and shall be clearly labeled as "chemical waste".

viii) All collected chemical waste shall be placed in an area designated for chemical waste storage.

4.2 Spill into the Marine Environment

This type of spill is considered the most serious in terms of the possibility of causing impact to the local cetacean community and other marine organisms. The notification system is separated into two scales, as determined by the area of spillage of 100 m2.

Upon spillage, we will use the standard Spill Kits available in the market. The standard Spill Kits includes items such as pads, pillow and Secondary Oil Containment (SOC). SOC is used to enclose the spillage area to contain the spillage spreading outside of the SOC. The pads and pillow are used for absorbing and removing the spillage within the SOC. Standard Spill Kits is attached in Appendix C.

It is the responsibility of the person observing the spill to report this immediately to their immediate supervisor who shall inform the Superintendent and General Manager (S&E) as Emergency Team Leader. The superintendent shall be assigned to deploy the Spill Kits to the spillage site. Depending on the scale of the spillage area of 100 m2, the report system is separated into the following two systems:

For the spillage area greater than 100 m2,

the report system is:

i) The General Manager (S&E) shall inform all parties such as Engineer Representative, Marine Department (MD), Fire Services Department (FSD), Agriculture, Fisheries and Conservation Department (AFCD), Environmental Protection Department (EPD), Environmental Team (ET) and Independent Environmental Checker (IEC) immediately. The contact of the parties tabulated in Section 8.0.

ii) The Emergency Team Leader shall be responsible for organizing the manpower to identify the spill source and stop or cease it.

iii) The Emergency Team Leader is the assigned person who shall equip all people involved in the cleanup works suitable personal protective equipment prior to the removal of any leaked chemical or chemical waste.

iv) The spillage area shall be contained by using secondary oil containment (SOC).

v) Pads and Pillow of the Spill Kit shall be applied to absorb and remove the spillage within the SOC. They will be collected by Disposal Bags as part of the Spill Kits item.

For the spillage area smaller than 100 m2,

the report system is:

i) The General Manager (S&E) shall inform the parties such as Engineer Representative, Environmental Team and Independent Environmental Checker immediately. The contact of the parties tabulated in Section 8.0.

ii) The Emergency Team Leader shall be responsible for organizing the manpower to identify the spill source and stop or cease it.

iii) The Emergency Team Leader is the assigned person who shall equip all people involved in the cleanup works suitable personal protective equipment prior to the removal of any leaked chemical or chemical waste.

iv) The spillage area shall be contained by using secondary oil containment (SOC).

v) Pads and Pillow of the Spill Kit shall be applied to absorb and remove the spillage within the SOC. They will be collected by Disposal Bags as part of the Spill Kits item.

4.3

Spillage Control Material

i)

The spillage control material

shall be distributed around the site at locations nearby to any storage of

chemicals or oil. A spillage control material located nearby to the Environmental Officer (EO) office shall

contain enough number of Spill Kits available on site. Also in a storage area immediate

adjacent to the EO office shall be a reasonable supply stock of Spill Kits available

to be deployed as necessary.

ii)

The pads and pillow of the Spill Kits used for spillage control by means

of physical absorption. No chemical or biological reaction would be carried out

during in the spillage control practices. Collection of pads and pillows

absorbing material is a must after completion of spillage removal.

iii)

The inventory of hazardous chemicals that will be used in this project

would be inspected periodically by superintendent(s) in a bi-monthly regular

basis.

iv)

At least 4 sets of Spill Kits would be provided on site in case of any

emergency and managed by the on shift superintendent or Emergency Team Leader��s

delegates. The Contractor provides sufficient numbers of spillage control kits

on site and total numbers of such kits would be discussed with ER.

4.4

Inventory of hazardous chemicals / compounds

i)

Basically, diesel would be the major chemical used on site for the HKBCF

project, lubricant is the other chemicals that stored on site for operation of

machineries.

ii)

Each sub-contractors provide the inventory of hazardous chemicals /

compound (other from diesel) used on site.

iii)

The superintendents will inspect the stock of hazardous chemicals /

compound together with the foremen of each sub-contractor.

iv)

Records of such hazardous chemicals / compound would be kept on site for

further inspection.

v)

All of the spillage control kits used for spillage removal would meet

EPD and Marine Departments�� requirement.

4.5

Protection of sensitive receivers

i)

Application of this section will apply if any one of the following

conditions are met:

A)

If the site area of spillage of chemical / hazardous compounds more than

100m2.

B)

The location of spillage relative to the water intakes, Tai Ho Wan Inlet

and coral sites such as Brothers Island is less than 1 km distance

ii)

Deployed a layer of physical absorbent at the water intakes, Tai Ho Wan

Inlet and coral site in order to protect such areas from the adverse affect due

to spillage.

iii)

The Contractor will inform the relevant parties as mentioned in Section 4.2.

iv)

The on shift superintendent or Emergency Team Leader��s delegates will

in- charge all the mitigate measures implement on site in order to minimize the

adverse effect.

v)

Follow the procedures as stated in Appendix B.

vi)

Scope of additional water quality monitoring would be implemented with

the agreement of ER, ET and IEC.

5. General dolphin contingency plan for petroleum/chemical spill event

It is not known to what ability Chinese White Dolphin (CWD) can detect chemicals within its environment. At best, cetaceans will be able to detect chemicals that float on the water surface that have a high viscosity (sludge like) but may not be able to detect more volatile fractions such as petrol/aviation fuel. As such, an emergency spill plan must provide for keeping CWD away form the effected area.

5.1 Initial Action

i) Observation from high platforms (the dolphin monitoring barge) or aerial surveys to determine the extent of the spill and record the number and location of any CWD within the area. As per the Dolphin Watch Plan[1] protocol, dolphins within the effected area can be visually and acoustically tracked to monitor risk and their specific reactions to the spill can be logged. This will help determine immediate and future risks.

ii) The course of action decided on will be related to such factors as the extent of the spill, the proximity of cetaceans to it and the likelihood of contact, e.g., enclosing the spill area or enclosing important habitats.

5.2. All

reasonable attempts must be made to keep dolphins away from contaminated

areas

i) The use of booms is an effective containment method and can also act as a barrier to dolphins. Deployment of such with concomitant visual and acoustic observations is appropriate for small and controllable spills that can be dealt with in the short term.

ii) In the event of larger spills, the deployment of barrier nets (such silt curtains or anti-shark nets) would be an effective means of keeping dolphins out of the contaminated area until such times as the area was free of contamination.

iii) If dolphins are detected within the boom/enclosed area which contains contaminants, the same protocol used to displace dolphins from behind silt curtains will be put into action, as described in the Dolphin Watch Plan.

6. Safety Equipment

The following is a list of the site safety equipment will be available;

i) Suitable fire extinguishers. There needs to be consideration regarding the flame retardant chemicals inside these devices do not exacerbate the problems that are occurring with a leak.

ii) Brushes, dustpans, mops and buckets.

iii) Dry sand and sawdust.

iv) Tissue and toweling (both paper and cloth).

v) Containers to receive waste including plastic bags, drums, etc.

vi) Spill Kits.

7. Implementation of the Spill Response Plan

7.1 Notification to workers and

frontier workforces

Personnel will receive information regarding the existence of a

Spill Response Plan during the site induction training carried out by the EO at

the site. This is correct since any

chemical spill is considered a safety and environmental issue with regards to the

workers at a site. It is also

normal that all workers involved with handling chemicals and oils shall be

supervised. For this reason it is important

that all site supervisors (foreman and superintendent) are trained in the

necessary procedures involved in containing a spill control practices. Then there are those workers that are

constantly involved in handling hazardous chemicals and oils. These workers shall also receive the

appropriate training with regards to the handling of a spill.

This training and briefing should be carried out by a member of the EO at the site area.

|

Trainer |

Notified the workers |

Participant |

|

Environmental Officer |

Worker safety Containment Clearing up Correct Disposal Reporting spills |

All workers All Supervisors All superintendents |

|

Types of sensitive receivers Locations of these receivers Methods to protect these receivers Need for prompt action |

Workers usually involved with hazardous chemicals or oil. All Supervisors All superintendents |

In case of a spill happening, the worker noticing a spill shall

immediately notify his supervisor. The supervisor shall then immediately

contact the Site Engineer / Foreman, EO and ER. Any or all of these people shall have

the responsibility to instruct the Emergency Team Leader or his delegate upon

the necessary course of action to contain the spill. All of these people shall report to the

area where the spill occurs to follow up on the action required to contain the

spill. The patrol boat would be immediately dispatched to the site of spill and

use the spillage control kit to contain the spill.

As soon as the spill has been noted by the foremen and/or superintendent,

and if any of the chemical or oil escaped into the marine environment, then relevant parties shall be notified for support as needed. Incident report after the incident would be

submitted to ER within 2 working days.

For the contacts of relevant parties please refer to section 8.0 for more details. The

Contractor will follow the procedures attached in Appendix B.

7.2 Training - workers and frontier workforces

All new workers will be introduced to the Spill Response Plan during the environmental induction training carried out by the Environmental Officer at the site. All workers at this site have to undergo such training. The EO shall periodically conduct Tool Box talks to the site workers. It is normal to conduct these at least once every month. They will be incorporated into the safety talks presented at this site. During such talks a demonstration of the containment methods and equipment shall be discussed and conducted.

7.3 Location of

Spill Kits

One set of spillage control kit

would be provided at site area WA2 and stored at the entrance of the Temporary

Chemical Waste Container.

Another 3 sets of Spill Kits

would be on the vessels at the marine works ready for use if spillage occurred.

2 sets of Spill Kits would be stored at patrol boat and 1 set of

Spill Kit would be placed at one of the working platform mounted on the barge

for dolphin watching. The working platform would be stationing at the site.

Site superintendent, foremen and

engineers would be notified by EO of the locations of the spillage control

kits.

8.

Contact of Relevant Parties

|

|

Name |

Telephone no. |

|

Emergency

Team |

||

|

General

Manager (S&E) |

Daniel Leung |

9877 4288 |

|

Environmental Officer |

C.M. Wong |

9717 7986 |

|

Environmental Supervisor |

Joy Chan |

9381 3259 |

|

Environmental Supervisor |

Arthur Lee |

6908 4007 |

|

Foreman |

Cheung Chu Kong |

9086 7666 |

|

Foreman |

Cheung Tak Fai |

9251 7371 |

|

Superintendent |

Alan Yeung Chung Chi |

9525 2813 |

|

Superintendent |

Tse Sui Ping |

6156 7937 |

|

|

||

|

Relevant Government Departments |

||

|

General

Emergency Services |

- |

999 |

|

Labour Department |

- |

2717 1717 |

|

Fire

Services Department |

- |

2723 2233 |

|

Agriculture, Fisheries and Conservation Department (AFCD) |

- |

2708 8885 |

|

Environmental Protection Department (EPD) |

- |

2838 3111 |

|

Nearest Fire Station |

Tung Chung Fire Station |

2988 1898 |

|

|

Chek Lap Kok Fire

Station |

2949 9081 |

|

Nearest

Ambulance Depot |

Tung Chung Ambulance

Depot |

2988 8282 |

|

|

|

2451 7193 |

|

Nearest

Hospital |

|

2468 5111 |

|

Airport

Authority Hong Kong |

- |

2186 7111 |

|

Weather Forecast |

- |

187 8200 |

|

Marine Department |

- |

2852 4472-77 |

|

Vessel Traffic Centre |

- |

2858 2163 , VHF channel 12 or 14 |

|

Marine Police Control Centre |

- |

2803 6241 |

|

Maritime Rescue Coordination Centre |

- |

2545 0181, 2233 7999 |

|

|

||

|

Relevant Utility Companies |

||

|

|

- |

2728 8333 |

|

China Gas Co. Ltd. |

- |

2880 6999 |

|

Water Supplies Department |

(Hong Kong & Island) |

2811 0788 |

|

|

( |

2396 0210 |

|

|

||

|

ER (Engineer Representatives) �V Ove Arup & Partners Ltd |

|

|

|

CRE |

Ir. Michael Lo |

6290 8860 |

|

SRE |

Ir. Ben Poon |

5180 0405 |

|

|

||

|

Environmental Team �V AECOM |

||

|

Environmental

Team Leader (ETL) |

Echo Leong |

3922 9280 |

|

|

||

|

Independent Environmental Checker �V

ENVIRON Hong Kong Limited |

||

|

IEC |

Raymond Dai |

3743 0788 |

9.

Role and Responsibilities of Management Parties

9.1 Emergency Team Leader - General Manager (S & E)

The General Manager

(S & E) is a representative of head office

responsible for ensuring commitment to environmental performance is fulfilled

and assigning adequate resources and facilities to provide an effective

environmental management programme on site.

9.2 Safety Manager (SM)

The Safety Manager (SM) is a

senior staff responsible for safety, health and environmental matter for the

Contract. He is also responsible

for general administration work of the safety and environmental divisions,

including recruitment, supervision and appraisal for safety officers and

environmental officers, meeting with safety officers and environmental officers

regularly. SM is also to assist in handling investigation of incidents and

accidents.

9.3 Construction Managers (CM)

The Construction Manager (CM) is a senior staff on site in which report to the Project Director has the responsibility to coordinate all environmental matters on site with all relative authorities. CM is also responsible for all site operations, management of environmental issues, staff supervision, control, coordination & planning, external liaison as well as implementing and monitoring necessary corrective actions. CM is working full-time on the site.

The Construction Manager will also carry out immediate action to rectify any non-compliance of environmental requirements as well as handle any complaints received from the public.

Construction Manager has the responsibility to coordinate all

environmental matters on site areas and to report these to the Site Safety and

Environmental Committee, HyD, EPD and Engineer��s Representatives. The

Construction Manager is also responsible for ensuring commitment to

environmental performance is fulfilled and assigning adequate resources and

facilities. With the assistance of the Environmental Officer, he would also

oversee the implementation and performance of the Spill Response Plan.

9.4 Environmental

Officer (EO)

The Environmental Officer will be appointed on site for the overall coordination, monitoring and overseeing the performance and implementation of the WMP for the Contract. The Environmental Officer directly reports to the Construction Manager.

The responsibilities of the Environmental Officer are also included as follows:

Ÿ Review the Spill Response Plan and ensure works are executed in accordance with the plan;

Ÿ Monitor and control the works including those of subcontractors to ensure compliance with specified requirements;

Ÿ Train the worker and frontier workforces;

Ÿ Assist in handling any complaints received; and

Ÿ Ensure regular environmental monitoring is carried out, and that all environmental monitoring results are recorded.

9.5 Environmental

Supervisor (ES)

Environmental Supervisor (ES) is responsible for the implementation of this Spill Response Plan with the assistance of the foreman. They are also responsible for:

Ÿ co-operate with the Environmental Officer to rectify any non-conformances being identified;

Ÿ attend

environmental meetings whenever necessary;

Ÿ carry

out ad hoc environmental site inspections when deficiencies are being found;

and

Ÿ assist with

Environmental Officer on any environmental accidents like chemical spillage.

9.6 Superintendents

/ Senior Foremen / Foremen

The Superintendent / Senior Foremen / Foremen are responsible for site supervision and coordination of the works as well as implementation of any remedial actions or environmental protection measures as directed by the CM / EO.

The Superintendent / Senior Foremen / Foremen are also responsible for:

Ÿ assisting

in the daily implementation of the Spill

Response Plan

including to ensure all waste is sorted, segregated, recycled or reused when

applicable;

Ÿ supervise the whole process of cleaning;

Ÿ ensuring

waste is avoided and/or minimised as much as practically possible and

Ÿ ensure waste is clean and stored in temporary chemical waste container before

left.

Ÿ

Superintendent shall be assigned to deploy the Spill Kits when a spillage occurs.

The workers are responsible to carry out the waste collection practice and follow the instruction of superintendent/senior foreman/ foreman. They are obligated to carry out the works like:

Ÿ trained before handling chemical spillage;

Ÿ pick up the Spill Kits

Ÿ transfer the Spill Kits to Site and

Ÿ collection of chemical wastes from site area and stored back to the temporary chemical storage area.

10

Notification the relevant parties

This will be the responsibility of the most senior and experienced worker involved and the immediate works supervisor. If the spill is small and contained easily, then the EO shall be informed and information will be given to the Engineer Representative (ER) as soon as practical. Both may choose to inspect the area if the spill is less than 100m2 to confirm that the spill is contained and the correct / most suitable clean up procedure has been implemented. In all cases of spillage, representative photographs shall be taken before and after clean up. If the spillage persists, daily photo records should be taken. The EO shall be responsible for keeping a record of the spill incidence.

Spills greater than site area 100m2 shall require both the EO and the ER to attend the area to check that the spill was contained and proper cleanup was carried out. A photograph record shall be kept, as shall be a record by both the EO and the ER. The Construction Manager /Engineer / Superintendent/ Foreman shall also be informed of the incident. If there was full containment and no significant quantity entered into the marine environment, then the event shall be documented.

If any significant quantity enters the marine environment (site area

100m2), then a full scale notification shall occur. Under such circumstances, identified

people in the relevant

parties shall be notified for support as needed, the contact of the relevant

parties listed in Section 8.0.

11 Emergency

Team Organization

Appendix A

General

Layout of the Site Area

Appendix B

Flow

Diagram of Handling the Spillage on Site

Appendix C

Information

of Spill Kits