table

of Contents

Executive

Summary

1 Introduction

1.1 Background

1.2 Scope of Report

1.3 Organization Structure

1.4 Summary of Construction Works

2 EM&A

Results

2.1 Air quality

2.2 Water Quality Monitoring

2.3 Dolphin Monitoring

2.4 EM&A Site Inspection

2.5 Waste Management Status

2.6 Environmental Licenses and

Permits

2.7 Implementation Status of

Environmental Mitigation Measures

2.8 Summary of Exceedances of the

Environmental Quality Performance Limit

2.9 Summary of Complaints,

Notification of Summons and Successful Prosecutions

3 Future

Key Issues

3.1 Construction Activities for

the Coming Quarter

3.2 Key Issues for the Coming

Quarter

3.3 Monitoring Schedule for the

Coming Quarter

4 Conclusions

Executive Summary

Under Contract

No. HY/2012/08, Dragages Bouygues Joint Venture (DBJV) is commissioned by

the Highways Department (HyD) to undertake the design and construction of the

Northern Connection Sub-sea Tunnel Section of the Tuen Mun Chek Lap Kok Link

Project (TM-CLK Link Project) while AECOM Asia Company Limited was

appointed by HyD as the Supervising Officer.

For implementation of the environmental monitoring and audit (EM&A)

programme under the Contract, ERM-Hong Kong, Limited (ERM) has been appointed

as the Environmental Team (ET) in accordance with Environmental Permit No. EP-354/2009/A.

Ramboll Hong Kong Ltd. was employed by HyD as the Independent Environmental

Checker (IEC) and Environmental Project Office (ENPO). Subsequent applications for

variation of environmental permits (VEP), EP-354/2009/B, EP-354/2009/C and EP-354/2009/D, were

granted on 28 January 2014, 10 December 2014 and 13 March 2015, respectively.

The construction phase of the Project commenced on 1

November 2013 and will tentatively be completed by the end of 2019. The impact monitoring of the EM&A programme,

including air quality, water quality, marine ecological monitoring and

environmental site inspections, were commenced on 1 November 2013.

This is the Eighteenth Quarterly EM&A report

presenting the EM&A works carried out during the period from 1 March 2018

to 31 May 2018 for the Contract No.

HY/2012/08 Northern

Connection Sub-sea Tunnel Section (the Project) in

accordance with the Updated EM&A Manual of the TM-CLK

Link Project. As informed by the

Contractor, the major activities in the reporting quarter included:

Land-based Works

·

Box Culvert Extension at Works Area Portion N-A;

·

Construction of North Ventilation Building Portion

N-C;

·

Construction of Cross Passage Tympanum TBM tunnel;

·

Cross Passage Lining Installation TBM Tunnel;

·

Cross Passage Construction by Pipe Jacking TBM

Tunnel;

·

Corbel & OVHD Construction TBM Tunnel;

·

Parapet wall and fireboard Installation TBM Tunnel;

·

Bulk Excavation Portion S-A; and

·

CSM treatment, Jet Grouting works and D-wall

Construction

·

Ground Freezing Works Portion S-A

A summary of monitoring and audit activities conducted

in the reporting period is listed below:

24-hour TSP Monitoring 31

sessions

1-hour TSP Monitoring 31

sessions

Impact Dolphin Monitoring 6 sessions

Joint Environmental Site Inspection 13 sessions

Implementation

of Marine Mammal Exclusion Zone

There was no dredging, reclamation or

marine sheet piling works in open waters during this reporting period.

Thus, Passive Acoustic Monitoring (PAM) and the day-time monitoring of Dolphin

Exclusion Zone (DEZ) by dolphin observers were not in effect during the

reporting period.

Summary of Breaches of Action/Limit Levels

Breaches of

Action and Limit Levels for Air Quality

Three (3) Action Level exceedances of 1-hour TSP were

recorded in the air quality monitoring of this reporting period. Investigation report is provided in Appendix I.

Dolphin Monitoring

Whilst

one (1) Limit Level exceedance was observed for the quarterly dolphin monitoring

data between March and May 2018, no unacceptable impact from the construction

activities of the TM-CLKL Northern Connection Sub-sea Tunnel Section on Chinese White Dolphins

was noticeable from general observations during the

dolphin monitoring in this reporting quarter.

Environmental

Complaints, Non-compliance & Summons

No

non-compliance with EIA recommendations, EP conditions and other requirements

associated with the construction of this Contract was recorded in this

reporting period.

No

environmental complaint was received in this reporting period.

No environmental summons was received in this

reporting period.

Reporting Change

There was no reporting change required in the

reporting period.

Upcoming Works for the Next Reporting Period

Works to be undertaken in the coming quarterly period

include the following:

Land-based Works

·

Box Culvert Extension at Works Area Portion N-A;

·

Construction of North Ventilation Building Portion

N-C;

·

Construction of Cross Passage Tympanum TBM tunnel;

·

Cross Passage Lining Installation TBM Tunnel;

·

Excavation of Sub-sea Tunnel TBM tunnel;

·

Parapet wall and fireboard Installation TBM Tunnel

·

Corbel Construction TBM Tunnel;

·

Bulk Excavation Portion S-A;

·

TBM Excavation Portion S-A; and

·

CSM treatment, Jet Grouting works and D-wall

Construction

Future Key Issues

Potential environmental impacts arising from the above

upcoming construction activities in the coming quarterly period are expected to

be mainly associated with dust, marine ecology and waste management issues.

1

Introduction

According to the findings of the Northwest New

Territories (NWNT) Traffic and Infrastructure Review conducted by the Transport

Department, Tuen Mun Road, Ting Kau Bridge, Lantau Link and North Lantau

Highway would be operating beyond capacity after 2016. This forecast has been based on the estimated

increase in cross boundary traffic, developments in the Northwest New Territories

(NWNT), and possible developments in North Lantau, including the Airport

developments, the Lantau Logistics Park (LLP) and the Hong Kong Zhuhai

Macao Bridge (HZMB). In order to cope

with the anticipated traffic demand, two new road sections between NWNT and

North Lantau Tuen Mun Chek Lap Kok Link (TM-CLKL) and Tuen Mun Western

Bypass (TMWB) are proposed.

An Environmental Impact Assessment (EIA) of TM-CLKL

(the Project) was prepared in accordance with the EIA Study Brief (No.

ESB-175/2007) and the Technical

Memorandum of the Environmental Impact Assessment Process (EIAO-TM). The EIA Report was submitted under the

Environmental Impact Assessment Ordinance (EIAO) in August 2009. Subsequent to the approval of the EIA Report

(EIAO Register Number AEIAR-146/2009), an Environmental Permit (EP-354/2009)

for TM-CLKL was granted by the Director of Environmental Protection (DEP) on 4

November 2009, and EP variation (VEP) (EP-354/2009/A) was issued on 8 December

2010. Subsequent applications for variation

of environmental permits (VEP), EP-354/2009/B,

EP-354/2009/C and EP-354/2009/D,

were granted on 28 January 2014, 10 December 2014 and 13 March 2015,

respectively.

Under Contract

No. HY/2012/08, Dragages Bouygues Joint Venture (DBJV) is commissioned by

the Highways Department (HyD) to undertake the design and construction of the

Northern Connection Sub-sea Tunnel Section of TM-CLKL while AECOM

Asia Company Limited was appointed by HyD as the Supervising Officer. For implementation of the environmental

monitoring and audit (EM&A) programme under the Contract, ERM-Hong Kong,

Limited (ERM) has been appointed as the Environmental Team (ET) in accordance

with Environmental Permit No. EP-354/2009/A. Ramboll Hong Kong Ltd.

was employed by HyD as the Independent Environmental Checker (IEC) and

Environmental Project Office (ENPO).

Layout of the Contract components is

presented in Figure 1.1.

The

construction phase of the Contract commenced on 1 November 2013 and will

tentatively be completed by the end of 2019.

The impact monitoring phase of the EM&A programme, including air

quality, water quality, marine ecological monitoring and environmental site

inspections, were commenced on 1 November 2013.

This is the Eighteenth Quarterly

EM&A Report under the Contract No. HY/2012/08

Tuen Mun Chek Lap Kok Link Northern Connection Sub-sea Tunnel Section.

This report presents a summary of the environmental monitoring and audit

works from 1 March 2018 to 31 May 2018.

1.3

Organization

Structure

The organization structure of the Contract is shown in

Appendix A. The

key personnel contact names and contact details are summarized in Table 1.1 below.

Table 1.1 Contact Information of Key Personnel

|

Party

|

Position

|

Name

|

Telephone

|

Fax

|

|

Highways

Department

|

Engr 22/HZMB

|

Chow Man Lung,

Andrew

|

2762 4110

|

2762 4110

|

|

SOR

(AECOM Asia

Company Limited)

|

Chief Resident

Engineer

|

Roger Man

Andrew

Westmoreland

|

2293 6388

2293 6360

|

2293 6300

2293 6300

|

|

ENPO / IEC

(Ramboll Hong

Kong Ltd.)

|

ENPO Leader

|

Y.H. Hui

|

3465

2850

|

3465 2899

|

|

IEC

|

Dr. F.C. Tsang

|

3465

2851

|

3465 2899

|

|

Contractor

(Dragages Bouygues Joint Venture)

|

Environmental

Officer

|

Bryan Lee

|

2293 7323

|

2293 7499

|

|

|

24-hour

complaint hotline

|

Rachel Lam

|

2293 7330

|

|

|

ET (ERM-HK)

|

ET Leader

|

Jovy Tam

|

2271 3113

|

2723 5660

|

The construction phase of this

Contract was commenced on 1 November 2013.

The construction programme is shown in Appendix

B.

As per DBJVs information, details

of major construction works carried out in this reporting period are summarized

in Table 1.2.

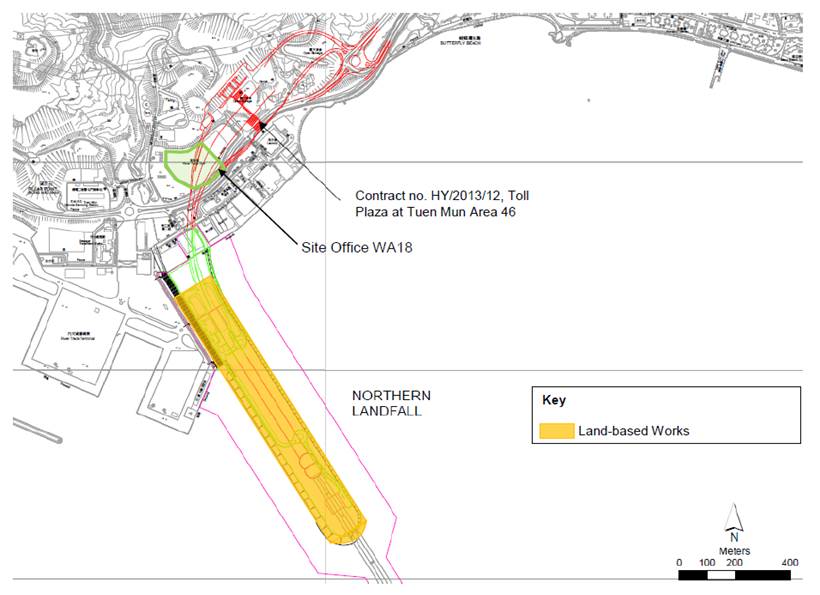

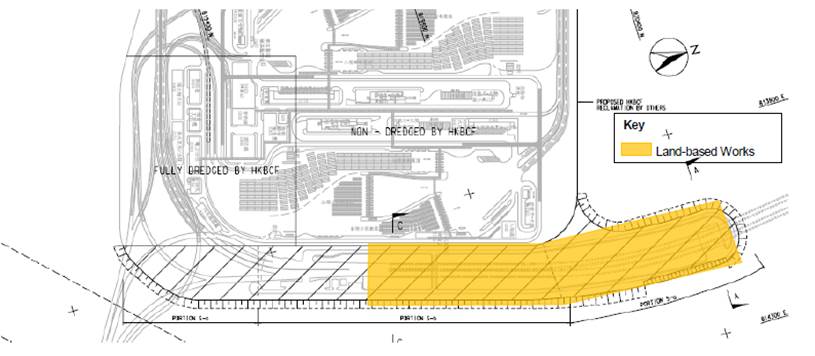

The general layout plan of the site showing the

detailed works areas is shown in Figure 1.2. The

Environmental Sensitive Receivers in the vicinity of the Project are shown in Figure 1.3.

The

implementation schedule of environmental mitigation measures is presented in Appendix C.

Table 1.2 Summary of Construction Activities Undertaken during the

Reporting Period

|

Construction Activities Undertaken

|

|

Land-based Works

|

|

·

Box Culvert Extension at Works Area Portion N-A;

·

Construction of North Ventilation Building Portion

N-C;

·

Construction of Cross Passage Tympanum TBM tunnel;

·

Cross Passage Lining Installation TBM Tunnel;

·

Cross Passage Construction by Pipe Jacking TBM

Tunnel;

·

Corbel & OVHD Construction TBM Tunnel;

·

Parapet wall and fireboard Installation TBM

Tunnel;

·

Bulk Excavation Portion S-A; and

·

CSM treatment, Jet Grouting works and D-wall

Construction

·

Ground Freezing Works Portion S-A

|

Figure 1.2 Locations of Construction Activities March to May 2018

2

EM&A Results

The EM&A programme required environmental

monitoring for air quality, water quality and marine ecology as well as environmental

site inspections for air quality, noise, water quality, waste management,

marine ecology and landscape and visual impacts. The EM&A requirements and related

findings for each component are summarized in the following sections

As per the requirements

under Condition 2.4 of EP-354/2009/D, the Enhanced TSP

Monitoring Plan has been prepared under Contract

No. HY/2012/08. Details of the

monitoring plan are presented in the Enhanced

TSP Monitoring Plan ().

2.1.1

Monitoring Requirements and Equipment

In accordance with the Updated EM&A Manual and the

Enhanced

TSP Monitoring Plan, impact 1-hour TSP monitoring was conducted three (3)

times in every six (6) days and impact 24-hour TSP monitoring was carried out

once in every six (6) days when the highest dust impact was expected. 1-hr and 24-hr TSP monitoring frequency was

increased to three times per day every three days and daily every three days

respectively as excavation works for launching shaft commenced on 24 October

2014.

High volume samplers (HVSs) were used to carry out the

1-hour and 24-hour TSP monitoring in the reporting quarter at the five (5) air

quality monitoring stations in accordance with the requirements stipulated in

the Updated EM&A Manual (Figure 2.1; Table 2.1). Wind anemometer was installed at the rooftop

of ASR5 for logging wind speed and wind direction. Details of the equipment deployed are

provided in Table 2.2.

Table 2.1 Locations of Impact Air Quality Monitoring Stations and

Monitoring Dates in this Reporting Period

|

Monitoring

Station

|

Monitoring

Dates

|

Location

|

Description

|

Parameters & Frequency

|

|

ASR1

|

2, 5, 8, 11, 14, 17, 20, 23, 26 and 29 March 2018

|

Tuen Mun Fireboat Station

|

Office

|

TSP monitoring

Ÿ 1-hour Total Suspended Particulates (1-hour TSP, ΅g/m3), 3

times in every 6 days

Ÿ 24-hour Total Suspended Particulates (24-hour TSP, ΅g/m3),

daily for 24-hour in every 6 days

Enhanced TSP monitoring

(commenced on 24 October 2014)

Ÿ 1-hour Total Suspended Particulates (1-hour TSP, ΅g/m3), 3

times in every 3 days

Ÿ 24-hour Total Suspended Particulates (24-hour TSP, ΅g/m3),

daily for 24-hour in every 3 days

|

|

ASR5

|

1, 4, 7, 10, 13, 16, 19, 22, 25 and 28 April 2018

|

Pillar Point Fire Station

|

Office

|

|

AQMS1

|

1, 4, 7, 10, 13, 16, 19, 22, 25, 28 and 31 May 2018

|

Previous River Trade Golf

|

Bare ground

|

|

ASR6

|

|

Butterfly Beach Laundry

|

Office

|

|

ASR10

|

|

Butterfly Beach Park

|

Recreational uses

|

Table

2.2 Air Quality

Monitoring Equipment

|

Equipment

|

Brand and Model

|

|

High Volume Sampler

(1-hour TSP and 24-hour TSP)

|

Tisch Environmental Mass Flow Controlled Total

Suspended Particulate (TSP) High Volume Sampler (Model No. TE-5170)

|

|

Wind Meter

|

Davis (Model: Vantage Pro 2 (S/N: AS160104014)

|

|

Wind Anemometer for calibration

|

Lutron (Model No. AM-4201)

|

2.1.2

Action & Limit Levels

The Action and Limit Levels of the air quality

monitoring is provided in Appendix D. The Event and Action plan is presented in Appendix H.

2.1.3

Monitoring Schedule for the Reporting Quarter

The schedules for air quality monitoring in the

reporting quarter are provided in Appendix E.

2.1.4

Results and Observations

Impact air quality monitoring was conducted at all

designated monitoring stations in the reporting period under favourable weather

conditions. The major dust sources in

the reporting period include construction activities under the Contract as well

as nearby traffic emissions.

The monitoring results for 1-hour TSP and 24-hour TSP

are summarized in Tables 2.3 and 2.4, respectively. Monitoring results are presented graphically

in Appendix F and detailed impact air quality monitoring

data were reported in the Fifty-third to Fifty-fifth Monthly EM&A Report.

Table 2.3 Summary of 1-hour TSP Monitoring Results in this Reporting

Period

|

Month/Year

|

Station

|

Average (΅g/m3)

|

Range (΅g/m3)

|

Action Level (΅g/m3)

|

Limit Level (΅g/m3)

|

|

March to May

2018

|

ASR 1

|

127

|

39

- 460

|

331

|

500

|

|

ASR 5

|

162

|

57

- 389

|

340

|

500

|

|

AQMS1

|

95

|

22

- 197

|

335

|

500

|

|

ASR6

|

116

|

33

- 295

|

338

|

500

|

|

ASR10

|

75

|

28

- 196

|

337

|

500

|

Table 2.4 Summary of 24-hour TSP Monitoring Results in this Reporting

Period

|

Month/Year

|

Station

|

Average (΅g/m3)

|

Range (΅g/m3)

|

Action Level (΅g/m3)

|

Limit Level (΅g/m3)

|

|

March to May

2018

|

ASR 1

|

86

|

30

- 176

|

213

|

260

|

|

ASR 5

|

94

|

62

- 179

|

238

|

260

|

|

AQMS1

|

63

|

36

- 124

|

213

|

260

|

|

ASR6

|

75

|

43

- 164

|

238

|

260

|

|

ASR10

|

54

|

24

- 132

|

214

|

260

|

Three (3) Action Level exceedances of 1-hour TSP were

recorded in the air quality monitoring of this reporting period. Summary of Exceedances for Air Quality Impact

Monitoring in this Reporting Quarter is detailed in Table 2.13.

2.2

Water

Quality Monitoring

Seawall Enhancement Works at Northern Landfall has

been completed on 31 December 2017.

Notification of suspension of water quality monitoring has been approved

by EPD on 2 March 2018. Water Quality

Monitoring will be resumed prior to the start of Seawall Modification Works at

Southern Landfall in January 2019.

2.3.1

Monitoring Requirements

Impact dolphin monitoring is required to be conducted

by a qualified dolphin specialist team to evaluate whether there have been any

effects on the dolphins. In order to

fulfil the EM&A requirements and make good use of available resources, the

on-going impact line transect dolphin monitoring data collected by HyDs Contract No. HY/2011/03 Hong Kong-Zhuhai-Macao Bridge. Hong Kong

Link Road - Section between Scenic Hill and Hong Kong Boundary Crossing

Facilities on the monthly basis is adopted to avoid duplicates of survey

effort.

2.3.2

Monitoring Equipment

Table 2.5 summarizes

the equipment used for the impact dolphin monitoring.

Table 2.5 Dolphin Monitoring Equipment

|

Equipment

|

Model

|

|

Global Positioning

System (GPS)

Camera

Laser Binoculars

Marine Binocular

Vessel for Monitoring

|

Garmin 18X-PC

Geo One Phottix

Nikon D90 300m 2.8D fixed focus

Nikon D90 20-300m zoom lens

Infinitor LRF 1000

Bushell 7 x 50 marine binocular with compass and reticules

65 foot single engine motor vessel with viewing platform 4.5m above

water level

|

2.3.3

Monitoring Parameter, Frequencies & Duration

Dolphin monitoring should cover all transect lines in

Northeast Lantau (NEL) and the Northwest Lantau (NWL) survey areas twice per

month throughout the entire construction period. The monitoring data should be compatible

with, and should be made available for, long-term studies of small cetacean

ecology in Hong Kong. In order to

provide a suitable long-term dataset for comparison, identical methodology and

line transects employed in baseline dolphin monitoring was followed in the

impact dolphin monitoring.

2.3.4

Monitoring Location

The impact dolphin monitoring was carried out in the

NEL and NWL along the line transect as depicted in Figure 2.2. The co-ordinates of all transect lines are

shown in Table 2.6 below.

Table

2.6 Impact Dolphin Monitoring Line Transect Co-ordinates

|

Line No.

|

Easting

|

Northing

|

Line No.

|

Easting

|

Northing

|

|

1

|

Start

Point

|

804671

|

815456

|

13

|

Start

Point

|

816506

|

819480

|

|

1

|

End

Point

|

804671

|

831404

|

13

|

End

Point

|

816506

|

824859

|

|

2

|

Start

Point

|

805476

|

820800*

|

14

|

Start

Point

|

817537

|

820220

|

|

2

|

End

Point

|

805476

|

826654

|

14

|

End

Point

|

817537

|

824613

|

|

3

|

Start

Point

|

806464

|

821150*

|

15

|

Start

Point

|

818568

|

820735

|

|

3

|

End

Point

|

806464

|

822911

|

15

|

End

Point

|

818568

|

824433

|

|

4

|

Start

Point

|

807518

|

821500*

|

16

|

Start

Point

|

819532

|

821420

|

|

4

|

End

Point

|

807518

|

829230

|

16

|

End

Point

|

819532

|

824209

|

|

5

|

Start

Point

|

808504

|

821850*

|

17

|

Start

Point

|

820451

|

822125

|

|

5

|

End

Point

|

808504

|

828602

|

17

|

End

Point

|

820451

|

823671

|

|

6

|

Start

Point

|

809490

|

822150*

|

18

|

Start

Point

|

821504

|

822371

|

|

6

|

End

Point

|

809490

|

825352

|

18

|

End

Point

|

821504

|

823761

|

|

7

|

Start

Point

|

810499

|

822000*

|

19

|

Start

Point

|

822513

|

823268

|

|

7

|

End

Point

|

810499

|

824613

|

19

|

End

Point

|

822513

|

824321

|

|

8

|

Start

Point

|

811508

|

821123

|

20

|

Start

Point

|

823477

|

823402

|

|

8

|

End

Point

|

811508

|

824254

|

20

|

End

Point

|

823477

|

824613

|

|

9

|

Start

Point

|

812516

|

821303

|

21

|

Start

Point

|

805476

|

827081

|

|

9

|

End

Point

|

812516

|

824254

|

21

|

End

Point

|

805476

|

830562

|

|

10

|

Start

Point

|

813525

|

821176

|

22

|

Start

Point

|

806464

|

824033

|

|

10

|

End

Point

|

813525

|

824657

|

22

|

End

Point

|

806464

|

829598

|

|

11

|

Start

Point

|

814556

|

818853

|

23

|

Start

Point

|

814559

|

821739

|

|

11

|

End

Point

|

814556

|

820992

|

23

|

End

Point

|

814559

|

824768

|

|

12

|

Start

Point

|

815542

|

818807

|

24*

|

Start Point

|

805476*

|

815900*

|

|

12

|

End

Point

|

815542

|

824882

|

24*

|

End Point

|

805476*

|

819100*

|

Remarks: The coordinates of several starting and ending

points have been revised since August 2017 due to the presence of a work zone

to the north of the airport platform with intense construction activities in

association with the construction of the third runway expansion for the Hong

Kong International Airport. Co-ordinates in red and

marked with asterisk are revised co-ordinates of transect line.

2.3.5

Action

& Limit

Levels

The Action and Limit levels of dolphin impact

monitoring are shown in Appendix D. The Event and Action plan is presented in Appendix H.

2.3.6

Monitoring Schedule for the Reporting Period

The dolphin monitoring schedules for the reporting

period are shown in Appendix E.

2.3.7

Results & Observations

A total of 791.83 km of survey effort was conducted,

with 89.8% of the total survey effort being conducted under

favourable weather conditions (ie Beaufort Sea State 3 or below with good

visibility) in this reporting quarter.

Amongst the two areas, 290.90 km and 500.93 km of survey effort were

conducted from NEL and NWL survey areas, respectively. The total survey effort conducted on primary

and secondary lines were 576.61 km and 215.22 km, respectively. The survey efforts are summarized in Appendix G.

A total of 9 groups of 30 Chinese White Dolphins

sightings were recorded during the six sets of surveys

in this reporting quarter. All dolphin sightings were made during on-effort search, and eight of

the nine on-effort dolphin sightings were made on primary lines.

During this reporting quarter, all dolphin groups were sighted in NWL,

while no dolphin was sighted

in NEL.

Encounter rates of Chinese White Dolphins are deduced from

the survey effort and on-effort sighting data made under favourable conditions

(Beaufort 3 or below with good visibility) in the reporting quarter with the

results and comparison with baseline results present in Tables 2.7 and 2.8.

Table 2.7 Individual Survey Event Encounter Rates

|

|

Encounter rate (STG) (no. of on-effort dolphin sightings per 100 km of

survey effort)

|

Encounter rate (ANI) (no. of dolphins from all on-effort sightings per

100 km of survey effort)

|

|

Primary Lines Only

|

Primary Lines Only

|

|

NEL

|

Set 1

(8 & 12 Mar)

|

0.00

|

0.00

|

|

Set 2

(20 & 23 Mar)

|

0.00

|

0.00

|

|

Set 3

(10 & 17 Apr)

|

0.00

|

0.00

|

|

Set 4

(19 & 25 Apr)

|

0.00

|

0.00

|

|

Set 5

(7 & 10 May)

|

0.00

|

0.00

|

|

Set 6

(16 & 30 May)

|

0.00

|

0.00

|

|

NWL

|

Set 1

(8 & 12 Mar)

|

1.73

|

5.19

|

|

Set 2

(20 & 23 Mar)

|

12.32

|

56.69

|

|

Set 3

(10 & 17 Apr)

|

0.00

|

0.00

|

|

Set 4

(19 & 25 Apr)

|

3.24

|

4.87

|

|

Set 5

(7 & 10 May)

|

0.00

|

0.00

|

|

Set 6

(16 & 30 May)

|

0.00

|

0.00

|

Note: Dolphin Encounter Rates are

deduced from the Two Sets of Surveys (Two Surveys in Each Set) in the reporting

quarter in Northeast (NEL) and Northwest Lantau (NWL)

Table 2.8 Quarterly Average Encounter Rates

|

|

Encounter rate (STG)

(no. of on-effort dolphin sightings per 100 km of

survey effort)

|

Encounter rate (ANI) (no. of dolphins from all

on-effort sightings per 100 km of survey effort)

|

|

March

May 2018

|

September November 2011

|

March

May 2018

|

September November 2011

|

|

Northeast Lantau

|

0.0

|

6.00

± 5.05

|

0.0

|

22.19

± 26.81

|

|

Northwest Lantau

|

2.88

± 4.81

|

9.85

± 5.85

|

11.12

± 22.46

|

44.66

± 29.85

|

Note: Encounter rates deduced from the

baseline monitoring period have been recalculated based only on survey effort

and on-effort sighting data made along the primary transect lines under

favourable conditions.

Table d 4.6

nd limit levels of dolphin impact monitoring are

shown in Table

Group size of Chinese White

Dolphins ranged from 1 - 8 individuals per group in North Lantau region during

March to May 2018. The average dolphin

group sizes from these three months were compared with the ones deduced from

the baseline period in September to November 2011, as shown in Table 2.9.

Table 2.9 Average Dolphin Group Size

|

|

Average Dolphin Group Size

|

|

March

May 2018

|

September November 2011

|

|

Overall

|

3.33

± 3.39 (n = 9)

|

3.72

± 3.13 (n = 66)

|

|

Northeast Lantau

|

---

|

3.18 ± 2.16 (n = 17)

|

|

Northwest Lantau

|

3.33

± 3.39 (n = 9)

|

3.92

± 3.40 (n = 49)

|

Whilst one limit level exceedance was observed for the

quarterly dolphin monitoring data between March and May 2018, no

unacceptable impact from the construction activities of this Contract was

recorded from the general observations.

Although the dolphins infrequently occurred along the

alignment of TM-CLKL Northern Connection Sub-Sea Tunnel Section in the past and

during the baseline monitoring period, it is apparent that dolphin usage has

been significantly reduced in NEL.

It is critical to monitor the dolphin usage in North

Lantau region in the upcoming quarters to determine whether the dolphins are

continuously affected by the various construction activities in relation to the

HZMB-related works, and whether suitable mitigation measure can be applied to

revert the situation.

2.3.8

Implementation of Marine Mammal Exclusion Zone

There was no dredging, reclamation or marine sheet piling works in

open waters during this reporting period. Thus, Passive Acoustic

Monitoring (PAM) and the day-time monitoring of Dolphin Exclusion Zone (DEZ) by

dolphin observers were not in effect during the reporting period.

Site inspections were carried out on a weekly basis to

monitor the implementation of proper environmental pollution control and

mitigation measures under the Contract.

Thirteen (13) site inspections were carried out in the reporting quarter

on 7, 14, 21 and 28 March 2018;

4, 11, 18 and 25 April 2018;

2, 9, 16, 23 and 30 May 2018.

Key observations during the site inspections in this

reporting period are summarized in Table

2.10.

Table 2.10 Specific Observations and Recommendations during the Weekly

Site Inspection in this Reporting Period

|

Inspection Date

|

Environmental Observations

|

Recommendations/ Remarks

|

|

7 March 2018

|

Works

Area Portion N-C

Ÿ Accumulated

waste in the waste container should be removed.

Ÿ Drip

tray should be provided for the oil drum.

Ÿ Cement

bags should be covered with tarpaulin sheeting.

Works

Area Portion S-A

Ÿ U-channel

should be installed for collection of rainwater.

Reminder

from SOR

Works

Area Portion S-A

Ÿ The

tip of excavator should be mounted with noise absorbent.

|

Works

Area Portion N-C

Ÿ The

Contractor was reminded to remove the accumulated waste in the waste

container.

Ÿ The

Contractor was reminded to provide drip tray for the oil drum.

Ÿ The

Contractor was reminded to cover the cement bags with tarpaulin sheeting.

Works

Area Portion S-A

Ÿ The

Contractor was reminded to install U-channel for collection of rainwater.

Reminder

from SOR

Works

Area Portion S-A

Ÿ The

Contractor was reminded to mount the tip of excavator with noise absorbent.

|

|

14

March 2018

|

Works

Area TBM tunnel

Ÿ Drip

tray should be provided for the chemical containers.

Ÿ Cement

bags should be covered with tarpaulin sheeting.

Works

Area Portion S-B

Ÿ Cement

bags should be covered with tarpaulin sheeting.

Ÿ Drip

tray should be provided for the chemical containers.

Ÿ Drip

tray should be provided for the chemical containers.

|

Works

Area TBM tunnel

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Ÿ The

Contractor was reminded to cover the cement bags with tarpaulin sheeting.

Works

Area Portion S-B

Ÿ The

Contractor was reminded to cover the cement bags with tarpaulin sheeting.

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

|

|

21 March 2018

|

Works

Area Portion N-C

Ÿ Drip

tray should be provided for the chemical containers.

Ÿ Cement

bags should be covered with tarpaulin sheeting.

Works

Area - Portion N-A

Ÿ Drip

tray should be provided for the chemical containers.

Works

Area - Portion S-A

Ÿ The

top and 3 sides of the grout mixer should be enclosed with impervious

sheeting.

Ÿ Drip

tray should be provided for the oil drums.

|

Works

Area Portion N-C

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Ÿ The

Contractor was reminded to cover the cement bags with tarpaulin sheeting.

Works

Area - Portion N-A

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Works

Area - Portion S-A

Ÿ The

Contractor was reminded to enclose the top and 3 sides of the grout mixer

with impervious sheeting.

Ÿ The

Contractor was reminded to provide drip tray for the oil drums.

|

|

28

March 2018

|

Works

Area - Portion N-C

Ÿ Drip

tray should be provided for the chemical containers.

Works

Area - Portion N-A

Ÿ Dusty

material should be covered with tarpaulin sheets.

Ÿ Proper

NRMM label should be displayed.

Works

Area - Portion S-C

Ÿ The

cement bags should be covered with impervious sheeting.

Works

Area - Portion S-B

Ÿ Drip

tray should be provided for the chemical containers.

Ÿ Drip

tray should be provided for the chemical containers.

Ÿ The

chemical should be stored properly..

|

Works

Area - Portion N-C

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Works

Area - Portion N-A

Ÿ The

Contractor was reminded to cover the dusty mateiral with tarpaulin sheetings.

Ÿ The

Contractor was reminded to display proper NRMM label.

Ÿ Works

Area - Portion S-C

Ÿ The

Contractor was reminded to cover the cement bags with impervious sheeting.

Works

Area - Portion S-B

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Ÿ The

Contractor was reminded to store the chemical properly.

|

|

4 April 2018

|

Works

Area Portion S-B

Ÿ The

cement bags should be covered with impervious sheeting.

Works

Area Portion N-C

Ÿ Stagnant

water should be pumped off to avoid mosquito larva breeding.

|

Works

Area Portion S-B

Ÿ The

Contractor was reminded to cover the cement bags with impervious sheeting.

Works

Area Portion N-C

Ÿ The

Contractor was reminded to pump off the stagnant water to avoid mosquito

breeding.

|

|

11 April 2018

|

Works

Area Portion S-B

Ÿ Drip

tray should be provided to the chemical containers.

Works

Area Portion N-C

Ÿ Stagnant

water should be pumped off to avoid mosquito larva breeding.

Works

Area Portion N-A

Ÿ Proper

NRMM label should be displayed.

Reminder

from SOR

Works

Area - Portion S-B

Ÿ The

broken water barriers should be replaced.

|

Works

Area Portion S-B

Ÿ The

Contractor was reminded to provide drip tray to the chemical containers.

Works

Area Portion N-C

Ÿ The

Contractor was reminded to pump off the stagnant water to avoid mosquito

breeding.

Works

Area Portion N-A

Ÿ The

Contractor was reminded to display proper NRMM label.

Reminder

from SOR

Works

Area - Portion S-B

Ÿ The

Contractor was reminded to replace the broken barriers.

|

|

18

April 2018

|

Works

Area TBM tunnel

Ÿ Drip

tray should be provided for the chemical containers.

Works

Area - Portion S-B

Ÿ NRMM

label should be displayed on the generator.

|

Works

Area TBM tunnel

Ÿ The

Contractor was reminded to provide drip tray to the chemical containers.

Works

Area - Portion S-B

Ÿ The

Contractor was reminded to display NRMM label on the generator.

|

|

25 April 2018

|

Works

Area - Portion S-B

Ÿ Proper

NRMM label should be displayed on the excavator.

Ÿ Drip

tray should be provided for the chemical containers

Works

Area - Portion N-C

Ÿ Faded

NRMM label should be replaced by standard NRMM label.

|

Works

Area - Portion S-B

Ÿ The

Contractor was reminded to display proper NRMM label on the excavator.

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Works

Area - Portion N-C

Ÿ The

Contractor was reminded to replace the faded NRMM label with standard NRMM

label.

|

|

2

May 2018

|

Works

Area Portion S-B

Ÿ Stagnent

water on the oil drum should be removed.

Works

Area Portion S-A

Ÿ Drip

tray should be provided for the oil drums.

Works

Area TBM tunnel

Ÿ Cement

bags should be covered with impervious sheeting.

Ÿ Drip

tray should be provided for the chemical containers.

Ÿ Drip

tray should be provided for the chemical containers.

|

Works

Area Portion S-B

Ÿ The

Contractor was reminded to remove stagnent water on the oil drum.

Works

Area Portion S-A

Ÿ The

Contractor was reminded to provide drip tray for the oil drums.

Works

Area TBM tunnel

Ÿ The

Contractor was reminded to cover the cement bags with impervious sheeting.

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

|

|

9 May 2018

|

Works

Area Portion S-B

Ÿ General

refuse should be removed.

Works

Area Portion N-C

Ÿ Drip

tray should be provided for the chemical containers.

Works

Area Portion N-A

Ÿ The

faded NRMM should be replaced by the standard NRMM label.

|

Works

Area Portion S-B

Ÿ The

Contractor was reminded to remove the general refuse.

Works

Area Portion N-C

Ÿ The

Contractor was reminded to provide drip tray for the chemical containers.

Works

Area Portion N-A

Ÿ The

Contractor was reminded to replace the faded NRMM label with the standard

NRMM label.

|

|

16

May 2018

|

Works

Area Portion N-A

Ÿ Stagnant

water in the drip tray should be removed.

Reminder from the SOR

Works

Area - Portion S-A

Ÿ The

tip of the excavator should be enclosed with noise abatement material.

|

Works

Area Portion N-A

Ÿ The

Contractor was reminded to remove the stagnant water in the drip tray.

Reminder from the SOR

Works

Area - Portion S-A

Ÿ The

Contractor was reminded to enclose the tip of the excavator with noise

abatement mateiral.

|

|

23 May 2018

|

Works

Area - Portion N-C

Ÿ Drip

tray should be provided to the chemical containers.

Ÿ Cement

bags should be covered with tarpaulin sheets.

Works

Area - Portion S-A

Ÿ Stagnant

water in the drip tray should be removed.

Works

Area - Portion S-B

Ÿ Accumulated

rubbish in the skip should be removed.

|

Works

Area - Portion N-C

Ÿ The

Contractor was reminded to provide drip tray to the chemical containers.

Ÿ The

Contractor was reminded to cover the cement nags with tarpaulin sheets.

Works

Area - Portion S-A

Ÿ The

Contractor was reminded to remove the stagnant water in the drip tray.

Works

Area - Portion S-B

Ÿ The

Contractor was reminded to remove the accumulated rubbish in the skip.

|

|

30

May 2018

|

Works

Area - Portion N-C

Ÿ Cement

bags should be covered with tarpaulin sheets.

Works

Area - Portion N-A

Ÿ Water

spraying should be applied more frequently during dry conditions.

Ÿ The

slope surface should be covered with impervious sheeting.

Works

Area - Portion S-B

Ÿ Cement

bags should be covered with tarpaulin sheets.

Ÿ Stagnant

water should be removed.

Ÿ Water

spraying should be applied more frequently during dry conditions.

Ÿ The

slope surface should be covered with impervious sheeting.

Reminder from the SOR:

Works

Area - Portion S-B

The

breaker tip should be wrapped with soundproof mat.

|

Works

Area - Portion N-C

Ÿ The

Contractor was reminded to cover the cement bags with tarpaulin sheets.

Works

Area - Portion N-A

Ÿ The

Contractor was reminded to apply water spraying more frequently during dry

conditions.

Ÿ The

Contractor was reminded to cover the slope surface with impervious sheeting.

Works

Area - Portion S-B

Ÿ The

Contractor was reminded to cover the cement bags with tarpaulin sheets.

Ÿ The

Contractor was reminded to remove the stagnant water.

Ÿ The

Contractor was reminded to apply water spraying more frequently during dry

conditions.

Ÿ The

Contractor was reminded to cover the slope surface with impervious sheeting.

Reminder from the SOR:

Works

Area - Portion S-B

The

Contractor was reminder to wrap the breaker tip with soundproof mat.

|

|

|

|

|

The Contractor has

rectified all of the observations as identified during environmental site

inspections in the reporting quarter.

The Contractor had submitted application form for

registration as chemical waste producer under the Contract. Sufficient numbers of receptacles were

available for general refuse collection and sorting.

Wastes generated during this reporting period include

mainly construction wastes (inert and non-inert) and chemical wastes. Reference

has been made to the waste flow table prepared by the Contractor (Appendix J). The

quantities of different types of wastes are summarized in Table 2.11.

Table 2.11 Quantities of Different Waste Generated in the Reporting Period

|

Month/Year

|

Inert Construction Waste (a)

(tonnes)

|

Inert Construction Waste Re-used

(tonnes)

|

Non-inert Construction Waste (b)

(tonnes)

|

Imported

Fill (tonnes) (d)

|

Recyclable Materials (c) (kg)

|

Chemical Wastes (kg)

|

Marine Sediment (m3)

|

|

|

Category L

|

Category M

(Mp & Mf)

|

|

March 2018

|

66,457

|

62,247

|

459

|

0

|

229,360

|

2,000

|

0

|

6,195

|

|

April 2018

|

123,942

|

50,648

|

281

|

56,192.51

|

195,550

|

8,600

|

0

|

1,957

|

|

May 2018

|

127,964

|

62,822

|

686

|

13,289

|

93,310

|

0

|

0

|

177

|

|

|

Notes:

|

|

|

|

(a) Inert

construction wastes include hard rock and large broken concrete, and

materials disposed as public fill.

(b) Non-inert

construction wastes include general refuse disposed at landfill.

(c) Recyclable

materials include metals, paper, cardboard, plastics, timber and others.

(d) The

origin of imported fill is from Contract

No. HY/2013/03.

|

|

|

|

|

|

|

|

|

|

|

|

The Contractor was advised to properly maintain on

site C&D materials and waste collection, sorting and recording system,

dispose of C&D materials and wastes at designated ground and maximize

reuse/ recycle of C&D materials and wastes.

The Contractor was also reminded to properly maintain the site tidiness

and dispose of the wastes accumulated on site regularly and properly.

For chemical waste containers, the Contractor was

reminded to treat properly and store temporarily in designated chemical waste

storage area on site in accordance with the Code of Practice on the Packaging,

Labelling and Storage of Chemical Wastes.

The status of environmental licensing and permit is

summarized in Table 2.12 below.

In response to the site audit findings, the

Contractors carried out all corrective actions.

A summary of the Implementation Schedule of

Environmental Mitigation Measures (EMIS) is presented in Appendix C. The necessary mitigation measures relevant to

this Contract were implemented properly.

For

air quality impact monitoring, a total of thirty-one monitoring events for both

1-hour TSP and 24-hour TSP were undertaken in which three (3) Action Level

exceedances of 1-hour TSP were recorded in the air quality monitoring of this

reporting period. (Table 2.13).

Table 2.13 Summary of

Exceedances for Air Quality Impact Monitoring in this Reporting Quarter

|

Station

|

Exceedance Level

|

Date of Exceedances

|

Number of Exceedances

|

|

1-hr TSP

|

24-hr TSP

|

1-hr TSP

|

24-hr TSP

|

|

QMS1

|

Action Level

|

-

|

-

|

-

|

-

|

|

Limit Level

|

-

|

-

|

-

|

-

|

|

ASR1

|

Action Level

|

2018-03-02

|

-

|

1

|

-

|

|

|

2018-03-20

|

-

|

1

|

-

|

|

Limit Level

|

-

|

-

|

-

|

-

|

|

ASR5

|

Action Level

|

2018-04-13

|

-

|

1

|

-

|

|

Limit Level

|

-

|

-

|

-

|

-

|

|

ASR6

|

Action Level

|

-

|

-

|

-

|

-

|

|

Limit Level

|

-

|

-

|

-

|

-

|

|

ASR10

|

Action Level

|

-

|

-

|

-

|

-

|

|

Limit Level

|

-

|

-

|

-

|

-

|

|

Total number of Action level Exceedances:

|

3

|

0

|

|

Total number of Limit level Exceedances:

|

0

|

0

|

|

One (1) Limit Level exceedance was observed for the

quarterly dolphin monitoring data between March and May 2018, whilst no

unacceptable impact from the construction activities of the TM-CLKL Northern

Connection Sub-sea Tunnel Section on Chinese White Dolphins was noticeable from

general observations.

Cumulative statistics are provided in Appendix I.

The Environmental Complaint Handling Procedure is

provided in Figure 2.3.

No

environmental complaint was received in this reporting period.

No environmental summons was received in this

reporting period.

Statistics on complaints, notifications of summons and

successful prosecutions are summarized in Appendix I.

3

Future Key Issues

As informed by the Contractor, the major works for the

Project in the coming quarter are summarized in Table 3.1.

Table 3.1 Construction Works to Be Undertaken in the Coming Quarter

|

Works to be undertaken

|

|

Land-based

Works

·

Box Culvert Extension at Works Area Portion N-A;

·

Construction of North Ventilation Building Portion

N-C;

·

Construction of Cross Passage Tympanum TBM tunnel;

·

Cross Passage Lining Installation TBM Tunnel;

·

Excavation of Sub-sea Tunnel TBM tunnel;

·

Parapet wall and fireboard Installation TBM Tunnel

·

Corbel Construction TBM Tunnel;

·

Bulk Excavation Portion S-A;

·

TBM Excavation Portion S-A; and

·

CSM treatment, Jet Grouting works and D-wall

Construction

|

3.2

Key

Issues for the Coming Quarter

Potential environmental impacts arising from the above

upcoming construction activities in the coming quarterly period are expected to

be mainly associated with dust, marine ecology and waste management issues.

Impact monitoring for air quality and marine ecology

(include dolphin monitoring) are scheduled to continue for the next reporting

period.

The

monitoring programme has been reviewed and was considered as adequate to cater

for the nature of works in progress. Change to the monitoring programme was thus not

considered to be necessary at this stage.

The monitoring programme will be evaluated as appropriate in the next

reporting period.

4

Conclusions

This Eighteenth Quarterly EM&A Report presents the

findings of the EM&A activities undertaken during the period from 1 March

2018 to 31 May 2018, in accordance with the Updated EM&A Manual and the

requirements of EP-354/2009/D.

Air quality (including 1-hour TSP and 24-hour TSP and

dolphin monitoring were carried out in the reporting period. Three (3) Action Level exceedances of 1-hour

TSP were recorded in the air quality monitoring of this reporting period.

A total of 9 groups of 30 Chinese White Dolphins

sightings were recorded during the six sets of surveys

in this reporting quarter. All dolphin sightings were made during on-effort search, and eight of

the nine on-effort dolphin sightings were made on primary lines. Whilst one limit level exceedance was

observed for the quarterly dolphin monitoring data between March and May 2018, no

unacceptable impact from the construction activities of this Contract was

recorded from the general observations. Although the dolphins infrequently occurred

along the alignment of TM-CLKL Northern Connection Sub-Sea Tunnel Section in

the past and during the baseline monitoring period, it is apparent that dolphin

usage has been significantly reduced in NEL.

It is critical to monitor the dolphin usage in North Lantau region in

the upcoming quarters, to determine whether the dolphins are continuously

affected by the various construction activities in relation to the construction

works of the Contract, and whether suitable mitigation measure can be applied

to improve the situation.

Thirteen weekly environmental site

inspections were carried out in the reporting period. Recommendations on remedial actions provided

for the deficiencies identified during the site audits were properly

implemented by the Contractor. No

non-compliance event was recorded during the reporting period.

The monitoring programme has been reviewed and was

considered as adequate to cater for the nature of works in progress. Change to the monitoring programme

was thus not recommended at this stage.

The monitoring programme will be evaluated as appropriate in the next

reporting period. The ET will keep track

on the construction works to confirm compliance of environmental requirements

and the proper implementation of all necessary mitigation measures.